Understanding common CO2 laser machine problems and solutions is essential for every user, whether you’re a DIY enthusiast, small business owner, or professional engraver. This guide explores how to handle the most frequent issues, all while highlighting why the CO2 laser machine from Monport stands out with its top-tier safety, performance, and cutting-edge features.

Discover the power and reliability of the Monport 60W CO2 Laser Engraver & Cutter (24" x 16") with Autofocus – your ultimate solution for any creative or professional laser project. If you're encountering issues while using a CO2 laser machine, you're not alone. Visit the official product page here: Monport 60W CO2 Laser Engraver & Cutter.

Monport 60W CO2 Laser Engraver & Cutter (24" x 16") with Autofocus - Machine

The Monport 60W CO2 Laser Engraver & Cutter offers:

-

A fireproof viewing window for ultimate safety

-

Autofocus functionality for effortless precision

-

A large 16" x 24" working area with pass-through capability

-

High-speed performance up to 800mm/s

-

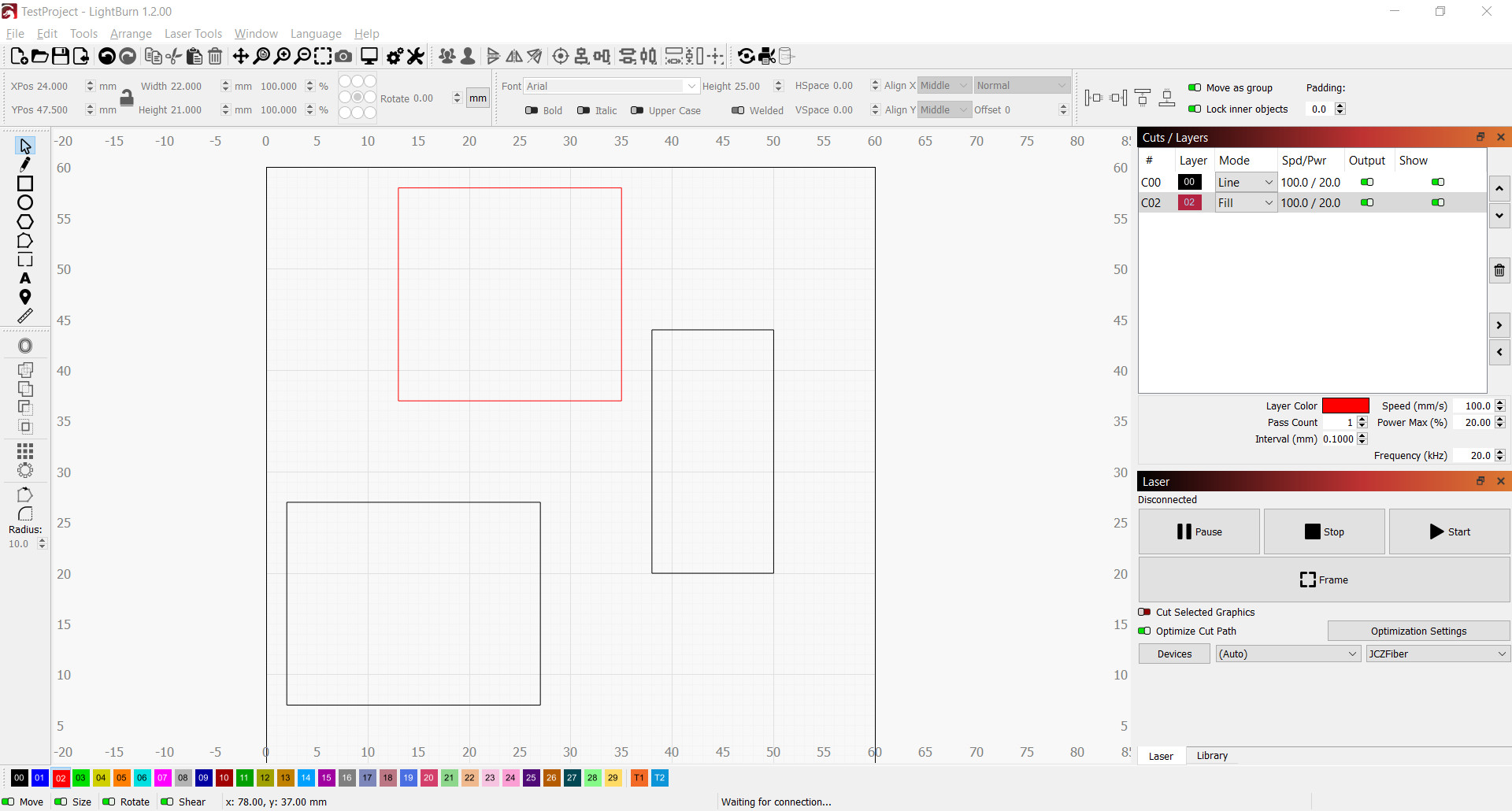

Compatibility with major software like LightBurn and AutoCAD

-

Built-in air assist and red dot guidance system

With these powerful features, Monport machines minimize risk and maximize productivity.

Laser Not Cutting Through Material Properly

One of the most reported CO2 laser machine problems is ineffective cutting. The laser either won’t cut through certain materials or produces inconsistent results. This is often due to incorrect settings, dirty lenses, or a misaligned laser path.

Fixes:

-

Check focus: Use the built-in Autofocus on the Monport 60W model to eliminate guesswork.

-

Clean optics: Clean your lens and mirrors regularly with approved laser lens wipes.

-

Air assist: The built-in air assist system on Monport clears debris and improves precision.

-

Speed and power settings: Adjust the engraving and cutting speed through the Ruida digital controller. The Monport supports up to 800 mm/s engraving speed, giving you a wide range of flexibility for different materials.

Project Ideas: Try cutting intricate wood jewelry boxes or layered acrylic signs with the precision this machine offers.

Inconsistent Engraving Depth or Quality

Are your engravings coming out too light or varying in depth? This is another of the common CO2 laser machine problems and solutions you’ll need to address.

Fixes:

-

Check material flatness: The Monport's working platform ensures a stable surface, but warped material can still cause uneven results.

-

Correct resolution settings: Monport delivers up to 4500 dpi, so make sure your design file matches that capability.

-

Use red dot guidance: The red dot pointer shows the exact laser position for better material alignment.

Engraving Ideas: Create high-resolution glassware logos or tiny leather patches with detailed text.

CO2 Laser Machine Not Responding to Software

One of the most frustrating issues is when your CO2 laser machine won’t communicate with the design software. The Monport 60W laser is built to eliminate this problem.

Fixes:

-

Triple connectivity options: With USB-to-PC, USB drive, and Ethernet ports, Monport ensures reliable connections.

-

Software compatibility: Whether you use LightBurn, CorelDRAW, or RDworks, Monport’s Ruida Controller supports it.

-

Driver installation: Ensure your computer has the correct drivers for the Ruida controller.

Design Ideas: Create customized laptop stands or engraved coasters by importing designs from LightBurn.

Thinking of upgrading your workshop? The Monport 60W CO2 Laser Machine is engineered for performance, safety, and ease of use. Explore more details here: Monport 60W CO2 Laser Engraver & Cutter

Machine Overheating or Producing Smoke

Heat management is key in laser cutting. If your CO2 laser machine overheats or smokes heavily, it can damage both the machine and materials.

Fixes:

-

Built-in air assist: Monport’s system blows away debris and heat from the cut zone.

-

Fireproof viewing window: Monport’s iron-framed window has a high ignition temperature over 1000°F, minimizing fire risk.

-

Keep ventilation open: Ensure your laser machine’s exhaust system is working and unobstructed.

Safe Engraving Projects: Engrave soft materials like bamboo, cork, or felt using safe heat levels supported by built-in airflow.

Autofocus or Alignment Not Working

Inaccurate focusing or misalignment causes major issues in engraving and cutting. Thankfully, the Monport 60W simplifies this with automatic features.

Fixes:

-

Use the control panel’s autofocus feature: With just a button press, you achieve the perfect laser height.

-

Red dot guidance: Visually track the path and alignment.

-

Manual testing: If autofocus seems off, verify by checking the focal distance (Monport uses 2.0” focus length).

Creative Uses: Try engraving unique shapes on ceramics or metal tags where alignment is critical.

Key Takeaways

-

Understanding common CO2 laser machine problems and solutions can save you time and money.

-

The Monport 60W CO2 laser machine is designed to eliminate many of these issues with smart automation, advanced optics, and high-speed capabilities.

-

From engraving glass to cutting acrylic, this machine handles it all with precision.

-

The machine's built-in safety features like fireproof windows, auto shutoff sensors, and laser protective glasses ensure peace of mind.

-

Connectivity and compatibility with top software tools make project creation smooth and efficient.

Frequently Asked Questions about Monport

Q: Can I use Monport with LightBurn?

A: Yes, Monport’s Ruida controller is fully compatible with LightBurn and other major design software like CorelDRAW and AutoCAD.

Q: Is the machine safe for indoor use?

A: Yes. The fireproof viewing window, automatic safety sensors, and laser protective glasses provide multiple layers of safety.

Q: How big is the working space?

A: The working area is 16" x 24" with a 1.5" x 28" pass-through, perfect for larger materials and batch jobs.

Q: Does the Monport 60W model come with autofocus?

A: Yes, and it is fully automated through the control panel.

Q: Is setup complicated for beginners?

A: No. Monport offers step-by-step manuals and responsive customer support to guide you through everything from assembly to first project.

Conclusion

When it comes to avoiding common CO2 laser machine problems and solutions, investing in a smart, efficient machine like the Monport 60W CO2 Laser Engraver & Cutter makes a major difference. From autofocus to software compatibility, this machine is built for smooth workflows, brilliant results, and long-term reliability.

Ready to say goodbye to laser frustration and start producing high-quality work?

Shop the Monport 60W CO2 Laser Engraver & Cutter today and experience the difference: Monport 60W CO2 Laser Engraver & Cutter (16"x24").