Glass engraving has long been celebrated for its exquisite beauty and the ability to transform simple pieces of glass into stunning works of art. The delicate translucency of glass offers a captivating canvas that captures and reflects light in unique ways, adding depth and dimension to designs. In the realm of artistic expression and personalized craftsmanship, the technique of laser engraving on glass has emerged as a game-changer. Utilizing advanced laser technology, artists and craftsmen can achieve unparalleled precision and intricacy in their designs, elevating the art of glass engraving to new heights. In this blog, we will delve into how to engrave glass using laser cutting machines, exploring the techniques, tools, and tips that enable artists to create breathtaking designs with ease and accuracy. Whether you are a professional engraver or a hobbyist looking to explore the world of glass artistry, understanding the nuances of laser engraving on glass can unlock a realm of creative possibilities. Join us as we embark on this artistic journey, uncovering the secrets to mastering the art of glass engraving with laser precision!

Understanding Glass Characteristics and Engraving Techniques

Glass, renowned for its unique properties of translucency and clarity, presents both a challenge and an opportunity for engravers. Its smooth and hard surface demands specialized techniques to ensure that the engraved design is both visible and aesthetically pleasing. Traditional methods of glass engraving often involve manual etching with diamond-tipped tools or abrasive blasting. While these methods can produce stunning results, they require a high level of skill and precision.

Advantages and Applicability of CO2 Laser Engraving

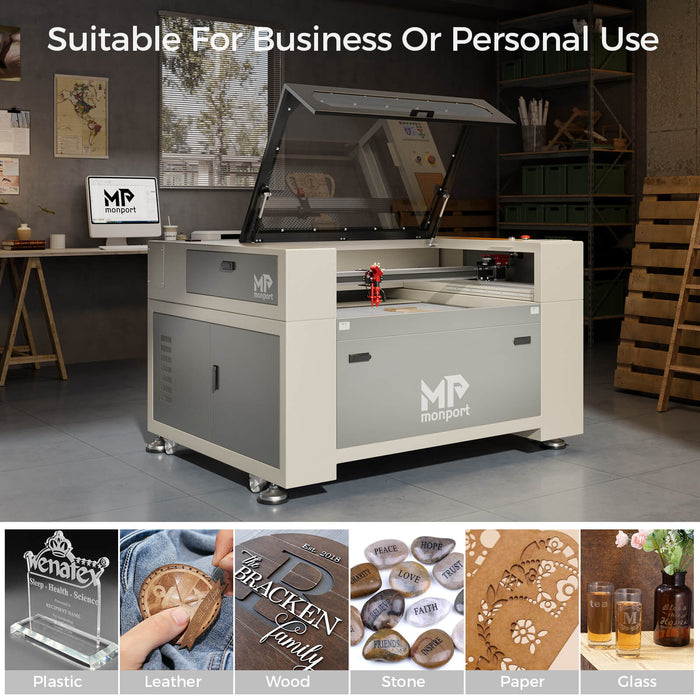

In recent years, CO2 laser engraving has emerged as a preferred method for engraving on glass due to its numerous advantages and adaptability. The focused beam of a CO2 laser can create intricate designs with fine details that are difficult to achieve with traditional methods. Moreover, CO2 laser engraving is a non-contact process, minimizing the risk of damaging the delicate surface of the glass.

- One of the key advantages of using CO2 laser engraving for glass is its versatility. Whether you are working with clear, colored, or textured glass, a CO2 laser cutting machine can be adjusted to suit the specific characteristics of the material, ensuring optimal results every time.

- Furthermore, CO2 laser engraving offers a high degree of repeatability, making it ideal for producing multiple identical pieces with consistent quality. This is particularly beneficial for commercial applications such as personalized gifts, awards, and decorative items where consistency and precision are paramount.

- Another significant advantage of CO2 laser engraving is its environmental friendliness. Unlike traditional methods that use chemicals or abrasive materials, CO2 laser engraving produces minimal waste, making it a more sustainable option.

The application of CO2 laser engraving on glass has revolutionized the art of glass engraving, offering artists, craftsmen, and businesses a powerful tool to unleash their creativity and achieve exceptional results. Whether you are looking to create intricate designs, produce high-quality commercial products, or simply explore the possibilities of glass artistry, CO2 laser engraving provides a versatile and efficient solution that is sure to impress.

How to Engrave Glass Using a CO2 Laser Engraving Machine

Engraving intricate designs on glass using a CO2 laser engraving machine can seem daunting, but with the right techniques and steps, it becomes a straightforward process. Here’s a step-by-step guide to help you achieve flawless results:

Step 1: Setting the Laser Engraving Machine Parameters

Before you begin engraving, it's crucial to set the parameters of the CO2 laser engraving machine according to the type and thickness of the glass you are using. Adjust the laser power, speed, and frequency to ensure optimal engraving results. It is advisable to perform a test run on a scrap piece of glass to fine-tune the settings and achieve the desired engraving depth and clarity.

Step 2: Securing the Glass Material and Pre-treatment

Secure the glass material firmly onto the engraving bed to prevent any movement during the engraving process. Ensure that the surface of the glass is clean and free from dust or fingerprints, as these can interfere with the engraving quality. Pre-treat the glass by applying a thin layer of marking spray or tape on the area to be engraved. This will help enhance the contrast and visibility of the engraved design.

Step 3: Initiating the Laser Engraving Process

Once the machine parameters are set and the glass material is prepared, you can proceed with the laser engraving process. Start the machine and carefully monitor the engraving progress to ensure that the design is being etched accurately and with the desired depth. It is essential to maintain a consistent speed and movement to achieve uniform engraving results.

Step 4: Post-Engraving Treatment and Cleaning

After the engraving is complete, carefully remove the glass from the engraving bed and inspect the engraved design for any imperfections or residue. Use a soft brush or cloth to gently remove any debris or particles from the engraved area. To enhance the visibility of the engraved design, you can clean the glass with a mild glass cleaner and polish it with a soft cloth.

Following these steps meticulously will enable you to master the art of glass engraving using a CO2 laser engraving machine, allowing you to create stunning and intricate designs with ease and precision.

Conclusion

The versatility, accuracy, and efficiency of CO2 laser engraving make it an indispensable tool for anyone looking to delve into the captivating world of glass artistry or enhance their existing engraving skills. With the right techniques and attention to detail, you can transform simple pieces of glass into stunning works of art that captivate and inspire.