Introduction

Stainless steel is a widely used material for various industrial and household products due to its excellent corrosion resistance, durability, and aesthetic appeal. However, traditional etching methods for stainless steel can be time-consuming and yield inconsistent results.

With the Monport GPro 60W Split MOPA Fiber Lazer Engraving & Marking Machine, you can easily and accurately laser engrave stainless steel for your customized projects. In this article, we will guide you through the process of using the Monport GPro 60W machine to lazer engrave stainless steel and provide you with tips and recommendations based on our experience.

Understanding the Monport GPro 60W Split MOPA Fiber Laser Engraver & Marking Machine

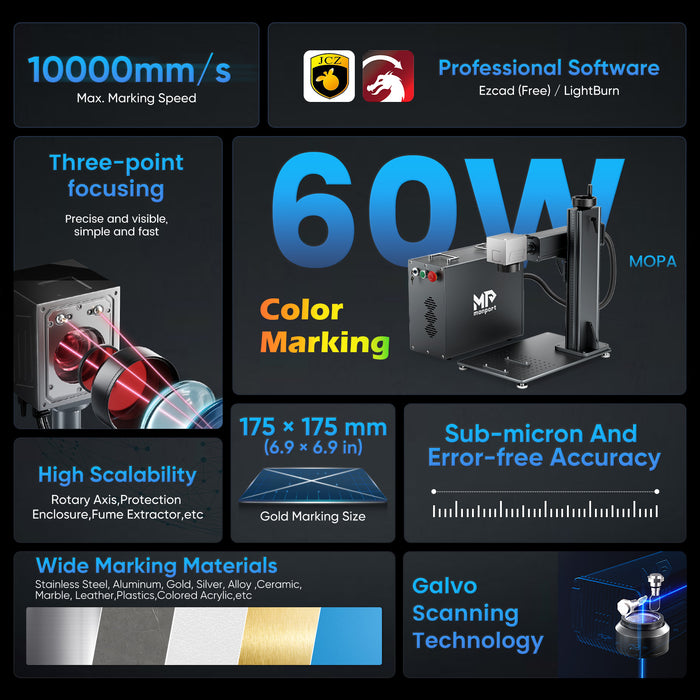

The Monport GPro 60W Split MOPA Fiber Laser Engraving & Marking Machine is a state-of-the-art lazer engraving machine with a manual focus feature. It uses fiber laser technology to deliver high-precision and high-quality engraving on stainless steel and other materials such as aluminum, brass, copper, gold, and silver.

The split MOPA design of the Monport GPro 60W machine allows users to adjust the pulse duration to fine-tune the laser output, which is crucial for achieving consistent and accurate lazer engraving results. It also features a high-speed galvanometer scanning system that ensures fast and seamless engraving of complex designs, making it an excellent choice for detailed and professional-grade engraving projects.

How to Laser Engrave Stainless Steel with the Monport GPro 60W Split MOPA Fiber Laser Engraver & Marking Machine

Here are the steps to laser engrave stainless steel with the Monport GPro 60W machine:

Step 1: Prepare your stainless steel material

Before lazer engraving your stainless steel material with the Monport GPro 60W machine, you need to ensure that it is clean and free from any contaminants such as dirt, grease, and oil. Use a clean cloth and rubbing alcohol to clean the surface of the stainless steel material thoroughly.

Step 2: Design and prepare your artwork

Create or import your design into the lazer engraving software that comes with the Monport GPro 60W machine. You can use various design software such as Adobe Illustrator, CorelDRAW, AutoCAD, or any other vector-based software that is compatible with the software.

When preparing your artwork, it is essential to consider the size and resolution of your design, which can affect the quality and clarity of the lazer engraving result. It is recommended to use a high resolution (at least 300 dpi) and an appropriate size that fits your stainless steel material.

Step 3: Set up the Monport GPro 60W machine

Connect the Monport GPro 60W machine to your computer and power it on. Open the lazer engraving software and adjust the machine parameters according to your design and material. You need to adjust the laser power, pulse duration, scanning speed, and focus to achieve the desired lazer engraving depth and linewidth.

The manual focus feature of the Monport GPro 60W machine allows users to adjust the focal length manually by rotating the focusing ring, which can provide precise control over the lazer engraving depth and sharpness.

Step 4: Start engraving

With the Monport GPro 60W machine set up, you can now start lazer engraving your stainless steel material. Place your material on the machine bed and press the start button on the software. The laser beam will scan over your design and lazer engraving it onto the stainless steel surface.

It is recommended to monitor the lazer engraving process closely to ensure that it is progressing correctly and adjust the parameters if necessary. Once the lazer engraving process is complete, remove the stainless steel material from the machine and inspect the lazer engraving result.creative-projects-and-ideas-with-a-fabric-laser-cutting-machine-and-laser-cut-acr

FAQs

What is the maximum engraving size of the Monport GPro 60W Split MOPA Fiber Laser Engraver & Marking Machine?

The maximum engraving size of the Monport GPro 60W machine is 200mm x 200mm. However, you can engrave larger designs by splitting them into smaller parts and engraving them separately.

What types of stainless steel materials can be laser engraved with the Monport GPro 60W machine?

The Monport GPro 60W machine can laser engrave various types of stainless steel materials, including austenitic, ferritic, and martensitic stainless steels. However, the engraving result may vary depending on the composition and surface finish of the stainless steel material.

How deep can the Monport GPro 60W machine engrave stainless steel?

The engraving depth of the Monport GPro 60W machine depends on various factors such as laser power, pulse duration, focus, and material. Typically, the engraving depth ranges from 0.01mm to 0.5mm, but it can be adjusted according to your requirements.

Important Details

When laser engraving stainless steel with the Monport GPro 60W machine, there are a few important details to keep in mind:

- The quality of the engraving result depends on the quality of the artwork and the parameters of the machine. It is recommended to use high-quality artwork and adjust the machine parameters according to your material and design.

- The Monport GPro 60W machine produces a lot of heat during the engraving process, which can affect the material's surface finish and cause discoloration. To avoid this, it is recommended to use a coolant or lubricant that can cool down the material and remove the debris created during the engraving process.

- The laser beam is invisible and can be hazardous to the eyes and skin. It is recommended to wear safety goggles and gloves when operating the Monport GPro 60W machine.

Takeaways

The Monport GPro 60W Split MOPA Fiber Laser Engraving & Marking Machine is an excellent tool for laser engraving stainless steel and other materials. With its high precision, consistent results, and versatility, it can help you achieve your customized projects quickly and efficiently.

When laser engraving stainless steel with the Monport GPro 60W machine, you need to prepare your material, design your artwork, set up the machine, and monitor the engraving process closely. By following these steps and keeping in mind the important details and recommendations we discussed, you can produce high-quality and professional-looking engraving results, perfect for a wide range of projects.

Effortless Laser Marking with Monport Black Laser Marking Spray

Looking to elevate your laser engraving projects? Monport Black Laser Marking Spray is the solution you’ve been waiting for. This high-performance aerosol spray is designed for use with CO2 laser engraving machines, ensuring easy and precise results with every application. Whether you're personalizing jewelry, customizing glassware, or serializing tools, this spray provides you with high-contrast, permanent marks that stand out.

The Benefits of Using Black Laser Marking Spray

-

Compatible with CO2 Laser Engraving Machines Designed for use with CO2 laser engraving machines of 25 watts and above, Monport Black Laser Marking Spray is the ideal companion for your engraving needs. It transforms your metal surfaces into highly legible, permanent black marks after laser engraving, making it perfect for a wide range of applications from metalwork to custom art pieces.

-

Permanent, High-Contrast Marks When you apply Monport Black Laser Marking Spray, the result is a high-contrast, dark black mark on your metal surface that is permanent and durable. This spray works on various metals, including aluminum, stainless steel, and brass. The fine-grained formula ensures deep penetration into the metal, producing heat-resistant markings that will last for years, even under challenging conditions.

-

Even and Powerful Application With the advanced spray technology in Monport Black Laser Marking Spray, you can achieve a smooth, even application every time. The 14 oz can features an anti-clog nozzle that guarantees no blockages, making the spray process both easy and efficient. The nanoparticle formula delivers more coverage with a thinner coating, which results in a professional-quality finish for all your metal marking projects.

-

Easy to Use and Quick Drying Using Monport Black Laser Marking Spray couldn’t be simpler. Just shake the can for 2 minutes, spray from a distance of 6 to 8 inches, and let the surface dry for 5 minutes. Once it’s dry, you’re ready to engrave, saving you valuable time. After engraving, rinse and wipe away the residue to reveal your crisp, dark black markings without any fuss.

-

Effortless Cleanup and Maintenance After marking your metal pieces, simply rinse and wipe the surface to reveal your high-contrast engraving. The black laser marking spray ensures there is no residue left behind, so your workpieces remain clean and ready for immediate use. The easy cleanup means that you can maintain a smooth and efficient workflow, whether you’re working on a small DIY project or a larger-scale production.

Why Choose Monport Black Laser Marking Spray?

Monport’s Black Laser Marking Spray is a game-changer for anyone looking to create durable, precise, and high-quality laser marks on metal surfaces. Its compatibility with CO2 lasers, combined with its easy application and cleanup, makes it an indispensable tool for professionals and hobbyists alike. With Monport Black Laser Marking Spray, you can be confident that your metal engraving projects will have permanent, high-contrast results every time.

Add this versatile spray to your toolkit today and experience effortless laser marking like never before!the-ultimate-affordable-laser-engraver-for-your-everyday-creations

Conclusion

Laser engraving stainless steel with the Monport GPro 60W Split MOPA Fiber Laser Engraver & Marking Machine is a simple and effective process that can help you achieve your custom design projects efficiently. By following the steps and tips we provided in this article, you can master the art of laser engraving stainless steel and create beautiful and durable products that will last for years. Laser engraving allows for precise, intricate designs on metal surfaces, ensuring high-quality results with every project.