Laser engraver projects spark creativity and excitement, where each design, logo, or heartfelt message takes on a life of its own on wooden surfaces. Yet, the journey doesn't end with the engraving; it's only the beginning.Taking the time to clean your laser engraver after engraving wood is essential for maintenance. In this friendly guide, we'll walk you through the essential steps of post-engraving wood care, sharing tips to bring out the best in your work and ensure a finish that shines with professionalism and pride when using a wood laser cutter.

Tips and Tricks

1. Wait for the Wood to Cool Down:

Before you begin cleaning, allow the wood to cool down completely. Laser engraving generates heat, which can cause the wood to become warm to the touch. Cleaning the wood while it's still hot may result in smudging or damage to the engraving. Patience is key to achieving optimal results.

2. Remove Residual Dust and Debris:

After the wood has cooled, gently brush away any residual dust and debris left behind by the laser engraving process. A soft-bristled brush or a clean, lint-free cloth can be used for this purpose. Pay close attention to the engraved areas, ensuring that all loose particles are removed.

3. Use Compressed Air:

For intricate engravings or hard-to-reach areas, compressed air can be highly effective. Use a can of compressed air to blow away any remaining dust and debris. This step helps to ensure that the surface is clean and ready for further cleaning.

4. Wipe Down with Isopropyl Alcohol:

Next, dampen a clean cloth with isopropyl alcohol (also known as rubbing alcohol). Gently wipe down the surface of the wood, focusing on the engraved areas. Isopropyl alcohol effectively removes oils, fingerprints, and other residues without damaging the wood or the engraving.

5. Let the Wood Dry Naturally:

Allow the wood to air dry completely after cleaning with isopropyl alcohol. Avoid using heat sources or wiping the wood with a cloth to speed up the drying process, as this may leave behind lint or streaks. Allowing the wood to dry naturally ensures a clean and streak-free finish.

6. Apply Wood Conditioner (Optional):

If desired, you can apply a wood conditioner to enhance the appearance of the engraving and protect the wood surface. Choose a high-quality wood conditioner and follow the manufacturer's instructions for application. This step is optional but can help to nourish the wood and bring out its natural beauty.

7. Inspect for Quality Assurance:

Once the wood is dry and any optional treatments have been applied, take a moment to inspect the engraved areas for quality assurance. Ensure that the engraving is clean, crisp, and free from any defects or imperfections. Make any necessary touch-ups or corrections as needed.

8. Consider Packaging and Presentation:

Finally, consider how you will package and present the laser-engraved wood item. Whether it's a personalized gift, a promotional item, or a decorative piece, thoughtful packaging can enhance the overall presentation and leave a lasting impression on the recipient.

By following these steps, you can effectively clean wood after laser engraving, ensuring a professional finish and maximizing the visual impact of your wood laser cutter projects. With proper care and attention to detail, your laser-engraved wood items will delight customers, clients, or loved ones for years to come.

Monport 80W CO2 Laser Engraver: The Powerhouse Engraving Tool

If you are on the hunt for a high-performing wood laser cutter that can handle big projects, look no further than the Monport 80W CO2 Laser Engraver with Autofocus. This engraving machine creates an all-in-one engraving solution and delivers exceptional quality, precision, and speed. Whether you're working on laser engraver projects for personal or business purposes, let's take a closer look at the features that make the Monport 80W CO2 Laser Engraver the best in the market.

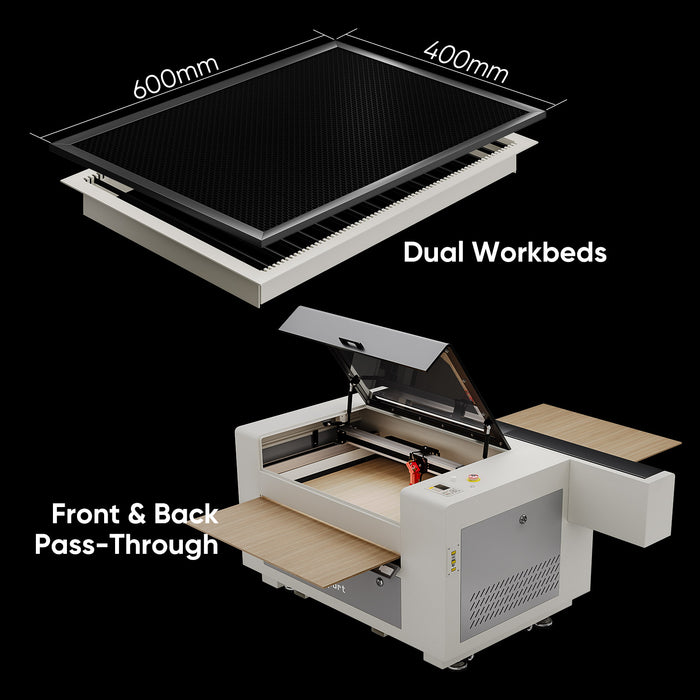

Spacious and Secure Work Bed

The Monport 80W CO2 Laser Engraver boasts a 24" x 16" spacious work bed, making it ideal for big projects that demand a larger surface area. The high-quality metal honeycomb board and aluminum panel offer double protection, and it can be moved for thicker materials, ensuring a stable and secure environment for your workpieces. It also features a four-way pass-through for items extending beyond the work bed.

Multiple Compatibility

The Monport 80W CO2 Laser Engraver is highly compatible with both Windows and Mac. It supports both RDWorks and LightBurn software systems, enabling precise control and engravings on various nonmetallic surfaces like wood, glass, and acrylic. With a depth of 0.59" and speeds up to 800mm/s, it makes a reliable and versatile engraver for both DIY and commercial use.

High-Performance Laser Beam

Monport and Yongli's joint research and development have produced a high-efficiency laser beam for the Monport 80W CO2 Laser Engraver, resulting in up to 12,000 hours of operation and a remarkable 6.5% higher actual RP compared to competitors with identical laser tube specifications. This high-performance laser beam ensures that every engraving project produces high-quality and precise outputs.

Intelligent Control Panel

The Monport 80W CO2 Laser Engraver runs on a Ruisin KT332N motherboard, offering direct control of the autofocus, Z-axis movement, and air assistance. It also features a dynamic display of the processing trajectory and progress, enabling users to modify layer parameters on the control panel with the added convenience of auto-saving. The system further supports power-off resume and provides accurate work time previews for an easy and efficient engraving process.

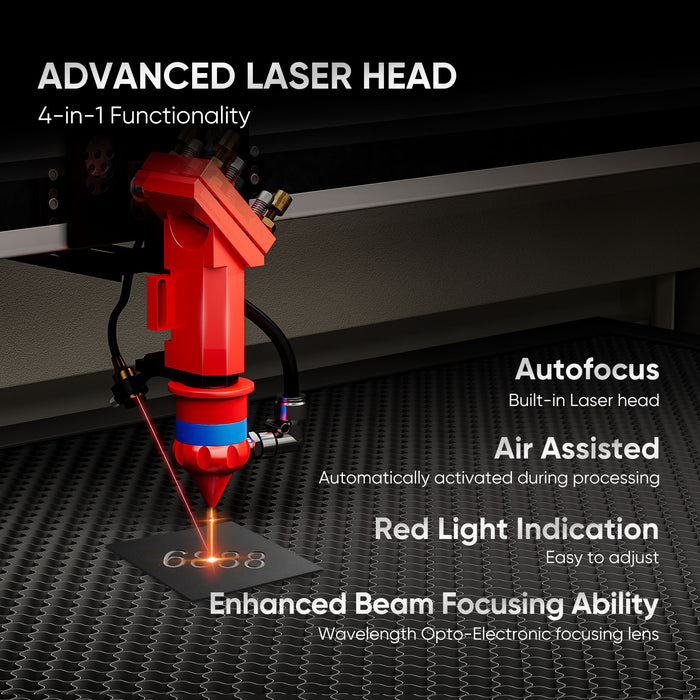

Advanced 4-in-1 Laser Head

Monport combines four different functions with a single laser head, including the laser emission, autofocus, air assist, and red light indication. The focusing lenses used are of high specifications, produced by Wavelength Optoelectronics, allowing for unparalleled carving and cutting experiences and streamlining the engraving process with convenience and efficiency, making it the best wood laser cutter for various applications.

Comprehensive Safety Features

The Monport 80W CO2 Laser Engraver ensures user safety at all times with features, including an emergency stop button for fast power shutdown, independent laser control with a dedicated key, cover protection to halt operation when opened, and auto-stop for low water or high temperature. It has a fireproof window for observation and built-in ventilation that instantly removes smoke, making it ideal for various laser engraver projects that demand both safety and high performance.

Frequently Asked Questions (FAQs)

Q1: Why is it important to clean wood after laser engraving?

A: Cleaning enhances the engraved design, removes harmful residue, and maintains your wood laser cutter’s longevity.

Q2: Can I use water instead of isopropyl alcohol to clean engraved wood?

A: It’s not recommended. Isopropyl alcohol evaporates quickly and doesn’t raise the grain of the wood like water can.

Q3: Will compressed air damage my laser engraver project?

A: Not at all—when used gently, compressed air safely removes fine dust and debris from delicate areas.

Q4: How often should I clean my wood laser cutter machine?

A: Ideally, after every use, especially after engraving wood, which produces more debris and residue.

Q5: What type of wood works best with the Monport 80W CO2 Laser Engraver?

A: Popular choices include birch plywood, maple, cherry, and MDF — all compatible and engrave beautifully with the Monport 80W.

Ready to Start Your Next Laser Engraver Project?

Take your laser engraving to the next level with the Monport 80W CO2 Laser Engraver. It’s the best wood laser cutter for anyone serious about precision, safety, and creative freedom.

Use code BESTMP39 at checkout – click here to shop!

Don’t miss out on this powerful, high-performance engraver built for big ideas!

Here's a video tutorial on how to make laser engraving projects with Monport 80W CO2 laser machine:

The Monport 80W CO2 Laser Engraver with Autofocus combines advanced features and high-performance laser technology, making it the best wood laser cutter for big projects. It provides versatility, precision, and speed, with unique features like the 4-in-1 laser head and comprehensive safety features. Experience the ultimate engraving experience with the Monport 80W CO2 Laser Engraver with Autofocus. Visit Monport Laser to enhance your engraving projects and unlock endless possibilities!