Ever wished your laser engravings offered more than just the standard black and white with How to Color Fill Your Laser Engravings? Craving the ability to add a splash of color and truly bring your creations to life? Dive into a world of vibrant creations: How to Color Fill Your Laser Engravings. A revolutionary technique that takes your laser etchings from simple to spectacular. This exciting approach transcends the limitations of traditional engraving, unlocking a whole new level of creative potential and transforming your projects into eye-catching masterpieces.

Color filling your laser engravings opens doors to a world of possibilities, allowing you to infuse your creations with vibrant hues and elevate your artistic expression with your MOPA color laser engraver. Whether you're looking to personalize gifts, create stunning signage, or bring your artistic vision to life, color filling offers the tools to captivate your audience and take your business ventures to the next level.

Monport 40W Pro Lightburn-Supported (12" X 8") CO2 Laser Engraver & Cutter with Air Assist - 40W Pro

ReadMore : Mastering Color Filling Techniques: A Guide to Enhancing Metal Engravings

What is Color Filling?

Traditional laser engraving results in a black or gray etching on the material's surface. Engraving color fill goes beyond that, adding a layer of color to the engraved areas using various techniques like paint application, oxidation, or layered materials. This creative upgrade breathes life into designs and enhances detail visibility—especially valuable for decorative, functional, and branded projects.

Monport’s advanced laser technology empowers you to embrace the world of engraving color fill and elevate your creative pursuits.

Unleash the Power of the Monport 40W Pro CO2 Laser Engraver

- Exceptional Speed and Precision: Breathe life into your designs with high-speed engraving of up to 350mm/s and unmatched accuracy of 0.01 inches. This machine tackles a variety of materials, including wood, glass, acrylic, and leather, delivering flawless results every time.

- Lightburn Compatibility: Unleash your creativity with seamless software integration. The 40W Pro is fully compatible with Lightburn, the industry-leading software, offering a vast array of design possibilities.

- Enhanced Precision with Built-in Air Assist: Achieve crystal-clear engravings with the integrated air assist feature. This technology minimizes carbonization effects, particularly when working with wood, ensuring superior detail and clarity.

- Upgraded Components for a Refined Experience: The Monport 40W Pro boasts a range of improvements, including a 19mm Adjustable Laser Head for versatile operation, Professional-Grade Metal Rails for enhanced stability, and a top-tier mirror holder for optimal laser performance.

- Effortless Project Management: Never miss a mark with the Red Dot Guidance feature. This innovative tool mounted on the laser head precisely highlights the laser's path, allowing for accurate placement of your cuts and engravings.

- Dual Work Bed for Maximum Versatility: The machine provides two work surface options: a stabilizer clamp to securely hold irregular objects and a vented level board for standard materials, accommodating a wider range of projects.

- Built-in Ventilation System: Maintain a safe working environment with the integrated fan that improves laser performance, ventilation, and reduces noise. Additionally, the exhaust port allows for safe fume removal.

Introducing the Monport GI30 MOPA Fiber Laser Engraver: A Revolution in Color Marking

- Full Color Marking: Take your designs to the next level with vibrant color marking capabilities on stainless steel and high-contrast engraving on anodized aluminum. The Monport GI30's 30W JPT MOPA fiber laser offers unmatched speed, precision, and flexibility.

- Adjustable Pulse Control: Fine-tune your designs with the ability to adjust pulse frequency and width, achieving the desired level of detail and color vibrancy.

- Innovative Design for Enhanced User Experience: Monport's GI30 redefines the fiber laser experience with a lighter weight, smaller size, and a user-friendly design. This innovative machine maintains exceptional performance while offering a more convenient and streamlined operation.

- Effortless Focusing with Electric Lifting: Achieve spot-on focus with the integrated electric lifting motor, ensuring precise marking results every time. This feature is particularly beneficial for beginners, simplifying the engraving process.

- Lightburn Compatibility for Seamless Operation: The GI30 comes equipped with EZCad 2.0 software and offers full compatibility with Lightburn, providing a user-friendly interface and a vast array of customizable features.

- Industry-Leading Heat Dissipation: The built-in air cooling system and unique side panel openings ensure optimal heat dissipation, maintaining the machine's peak performance.

Monport's commitment to quality extends beyond technical specifications

- Durable Construction: The casing crafted from anodized aluminum oxide provides a high-quality texture and robust build.

- Safety First: All sharp parts are chamfered or filleted, prioritizing user safety.

- Extended Machine Lifespan: Dust shields at the back of the work area protect the machine's internal components, ensuring long-lasting performance.

- Jumpstart Your Creativity: A complimentary rich material pack lets you begin your creative journey right away.

How to Color Fill your Laser Engravings?

The process varies depending on the material you're working with. Here's a closer look at two common materials. Watch this video on how to color fill your laser engravings using Monport GI30 color laser engraver.

-

Non-Metallic Materials (Plastics, Wood, Acrylic, Leather):

- Limited Natural Color Change: Unlike metals, these materials don't exhibit inherent color variations during laser engraving.

-

Coloring Techniques:

- Pre-Colored Materials: Embrace the inherent colors within the material itself. Opt for acrylic sheets available in a vast spectrum of vibrant hues, or utilize wood pre-treated with dyes or stains. The laser engraving process will reveal the contrasting color hidden beneath the surface, creating a stunning two-toned effect.

-

Paint Application: This method offers extensive creative freedom. Apply paint directly to the engraved areas using various techniques:

- Brushing: For broader coverage and detailed work.

- Wiping: Achieve a subtle, antique-like finish.

- Stencils: Create intricate designs and lettering with crisp lines.

-

Metals:

- Natural Oxidation: High-powered lasers can induce a chemical reaction on certain metals like stainless steel and titanium. This process, called oxidation, creates a thin layer of oxide on the metal surface, resulting in vibrant colors like gold, blue, and black.

- Grating Method: For metals that don't exhibit natural color variations during oxidation, a colored oxide layer can be applied beforehand. The laser beam then interacts with this pre-applied layer, selectively removing portions to reveal the desired color underneath.

Choosing the Right Materials and Color Laser Engraver

-

Monport Desktop 40w CO2 Laser: This color laser engraver is specifically designed for non-metallic materials like:

- Plastics (e.g., acrylic, polyethylene)

- Wood

- Acrylic

- Leather

- Monport MOPA GI Series: Designed specifically for metals, this laser offers precise engraving and the ability to leverage the natural oxidation process for color creation on compatible metals.

Remember: When using the Monport 40W CO2 Laser engraver for color filling, primarily rely on pre-colored materials or paint application techniques. The Monport GI30 MOPA fiber laser excels at utilizing the natural oxidation process and grating method for color creation on compatible metals.

Color Filling Techniques

Here's a step-by-step guide how to color fill your laser engravings:

-

Prepare your engraved piece: Ensure the engraved surface is clean and free of dust or debris. You can use a microfiber cloth or compressed air for cleaning.

-

Choose your paint: Select a paint suitable for the material you're working with. Acrylic paints are a popular choice for both wood and non-metallic materials. Opt for high-quality paints that adhere well to the engraved surface.

-

Apply the paint: There are several methods for paint application:

- Brushing: For broader coverage and detailed work, use a fine-tipped brush. Apply a thin layer of paint, focusing on filling the engraved areas.

- Wiping: For a subtle, antique-like finish, apply a thin layer of paint and then gently wipe away the excess with a soft cloth, leaving color primarily within the engravings.

- Stencils: Create crisp lines and intricate designs with stencils. Secure the stencil onto the engraved surface and apply paint using a brush or a small sponge.

-

Multiple coats (optional): Depending on the desired color vibrancy, you may need to apply additional coats of paint. Allow each layer to dry completely before applying the next.

-

Cleaning and finishing: Once the paint is dry, carefully remove any excess paint around the engraved area using a cotton swab dipped in rubbing alcohol (for non-metallic materials) or a suitable solvent (check compatibility for metals).

Additional Tips:

- Software plays a crucial role: Utilize Lightburn software, compatible with both Monport machines, to design your artwork and control the laser precisely. Lightburn offers features like image editing, layer control, and power settings to optimize your color filling process.

- Experimentation is key: Practice on scrap materials to test different color combinations, paint application techniques, and laser settings before working on your final project.

- Safety First: Always wear proper eye protection when operating the laser and ensure adequate ventilation in your workspace.

By understanding the potential of Monport's laser technology, color filling techniques, and safety measures of your color laser engraver, you can unlock a world of creative possibilities. From personalized gifts and eye-catching signage to artistic masterpieces, color filling adds a new dimension to your laser engraving projects.

Exploring the Creative Potential of Color Filling with Laser Engraver:

Color filling opens a treasure trove of creative possibilities for your laser engraving projects:

- Personalized gifts: Imagine creating unique keychains, phone cases, or photo frames with stunning color accents, adding a personal touch that goes beyond the ordinary.

- Eye-catching signage: Design vibrant signs and labels that grab attention and leave a lasting impression.

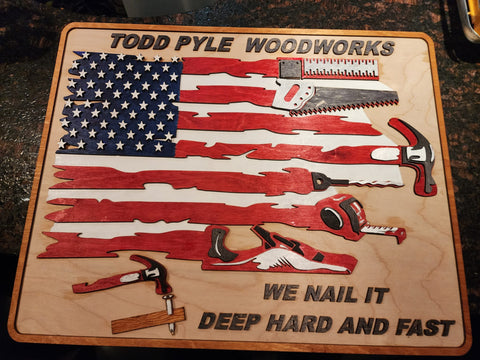

- Artistic creations: Combine laser engraving with color filling to produce mesmerizing wall art, decorative plaques, or coasters, transforming your artistic vision into a tangible masterpiece.

Beyond the aesthetics, color filling offers practical advantages:

- Enhanced visibility: Incorporate color to highlight important information on signage or create clear distinctions in complex designs.

- Branding opportunities: Integrate your brand colors into your creations, fostering brand recognition and establishing a consistent visual identity.

Unlock Flawless Metal Marking with Monport Black Laser Marking Spray

When it comes to creating professional-grade metal engravings, Monport black laser marking spray is a must-have for makers, hobbyists, and professionals alike. This powerful aerosol spray is specially formulated to work with CO2 laser machines of 25 watts and above, producing permanent black markings with exceptional contrast. Whether you're working on stainless steel, brass, or aluminum, the black laser marking spray bonds effortlessly to the surface, allowing for detailed and precise designs. Its fine-particle formula and anti-clog nozzle ensure smooth, even coverage every time. Drying in just five minutes, the black laser marking spray is easy to use and leaves no sticky residue after rinsing. From customizing jewelry to labeling tools or decorating metalware, the black laser marking spray from Monport delivers clean, bold results that last.

FAQs About Engraving Color Fill

Q: Can engraving color fill be used on all materials?

A: Most materials, but techniques differ: paint for wood and plastics, oxidation or coatings for metals.

Q: Which laser is best for color fill engraving?

A: Monport GI30 MOPA for metals; Monport 40W CO2 for non-metals and painted fills.

Q: Do I need special paint?

A: Yes, use acrylic or materials-specific coatings that adhere well to engraved surfaces.

Q: Will the color fill wear off?

A: Properly applied and sealed color fill is durable for both decorative and functional uses.

Q: Can beginners use color fill techniques?

A: Absolutely. It’s beginner-friendly and widely featured in laser engraving projects.

Conclusion

Color fill engraving transforms laser engraving from a simple marking method into a powerful tool for creativity and business growth. By choosing the right materials, techniques, and lasers like Monport 40W CO2 or GI30 MOPA fiber laser, you can create vibrant, lasting masterpieces.

Don’t wait — use code BESTMP10 at checkout and click here to shop now!