Introduction

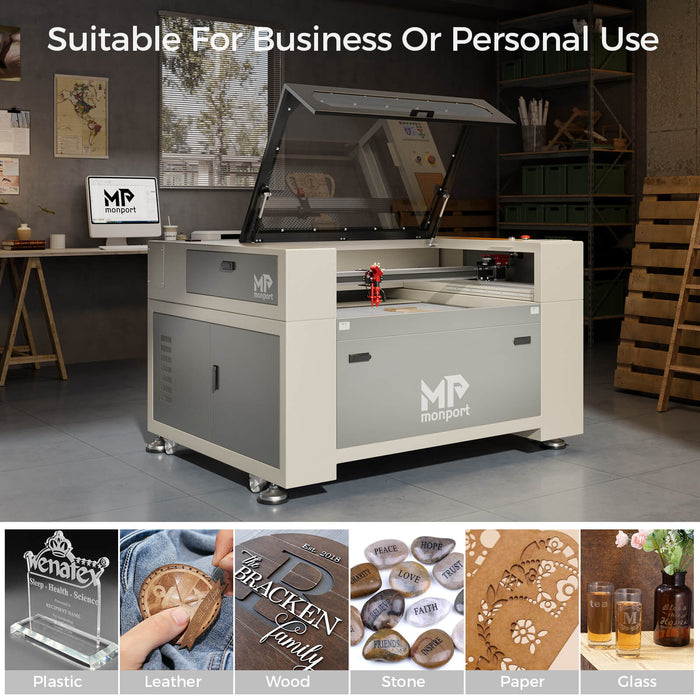

Having a laser engraving machine is a fun and interesting hobby. Commercial laser engravings machines are friendly and safe for everyone as long as the safety rules of laser engravings machine operation are followed. Monport has always prioritized the user experience of carving machines in order to make the carving field more convenient, simple, safe, and free. This blog will focus primarily on Monport's fire safety equipment.

Can a Laser Engraver Start a Fire?

A CO2 laser engraver can potentially start a fire if proper precautions are not taken. CO2 laser engravers use a high-powered laser beam to cut or engrave various materials such as wood, acrylic, paper, fabric, and other materials. The laser beam can generate a significant amount of heat, which can ignite the material being engraved if the heat is concentrated in one area for too long.

Prevent a Laser Fire with Monport Fire Safety Set

The Monport Fire Safety Set is a comprehensive safety kit designed to help prevent fire accidents when using a CO2 laser cutter. This safety set includes a range of essential safety equipment and accessories that can help reduce the risk of fire and it is fireproof safe for home while using the laser cutter.

Fireproof Viewing window

Polycarbonate plate (PC) is made of polycarbonate polymer with advanced formula and the latest extrusion technology. The PC board is a new type of high-strength transparent material and is the best material to replace glass and plexiglass.

The PC board has excellent properties such as lightweight, weather resistance, super strength, flame retardant, and sound insulation.

Most of the observation windows of CO2 laser engravings machines are made of acrylic plates. Acrylic acid is an important plastic polymer material developed earlier. It is easy to burn, and its oxygen index is only 17.3, so it will not spontaneously ignite, but it is a flammable product.

Acrylic can not isolate and digest the heat generated by the high-power engravings machine during the engravings process. Acrylic inevitably has fire safety problems to a certain extent. Therefore, Monport launches fireproof viewing windows to ensure the safety of engravers as much as possible.

Powerful ventilation system

A ventilation system is essential for removing smoke and fumes generated during the engravings process. The system should be designed to provide adequate ventilation for the specific size and type of laser engraver being used. A qualified professional should install and maintain the system. For your smoke ventilation, Monport Fireproof Series is equipped with air assists.

Honeycomb bed

The honeycomb can help to make the laser beam safer to work with by reducing the overall power density of the beam. This can be important for applications where the laser beam needs to be directed at people or sensitive equipment.

The honeycomb can be used to shape and control the beam in a variety of ways, depending on the specific application. For example, the honeycomb can be used to focus the beam onto a smaller area or to widen the beam for wider coverage.

Air assist

An air assist system can help remove debris and fumes generated during the engraving process. This can reduce the buildup of flammable materials, which can lower the risk of fire.

An air assist system can help keep the laser lens clean. A dirty lens can cause the laser to focus improperly, which can increase the risk of a fire. By keeping the lens clean, an air assist system can help ensure that the laser is operating at its optimal level and reduce the risk of a fire.

It can help cool the material being engraved. As the laser heats the material, it can create a thermal buildup, which can also increase the risk of a fire. By cooling the material, an air assist system can help prevent this buildup and reduce the risk of a fire.

Overall, using an air assist system with a laser engraver can help prevent fire accidents by reducing the buildup of flammable materials, keeping the laser lens clean, and cooling the material being engraved. However, it is important to ensure that the air assist system is properly installed, maintained, and used in accordance with the manufacturer's instructions to ensure that it is effective in preventing fire accidents.

How do you Prevent a Laser Fire?

Use the laser engraver in a well-ventilated area

The engraving process can produce smoke and fumes, which can be combustible. Proper ventilation can help prevent the accumulation of these materials and reduce the risk of fire.

Keep the work area free of flammable materials

Make sure there are no materials such as paper, cardboard, or fabric in the immediate vicinity of the laser engraver, as they could easily catch fire if exposed to the laser beam.

Use appropriate materials for engraving

Choose materials that are safe to engrave, such as wood, acrylic, or glass. Avoid materials that are known to be flammable, such as certain plastics or foam.

Monitor the laser engraver during operation

Never leave the laser engraver unattended while it is in operation. If you need to step away from the laser, be sure to turn it off first.

Use appropriate safety gear

Wear appropriate personal protective equipment, such as safety glasses or goggles, to protect your eyes from the laser beam.

Have a fire extinguisher nearby

Keep a fire extinguisher within reach in case of an emergency.

Conclusion

Your family laser business and family safety cannot withstand the intrusion of fire, so a new engraving machine with maximum security can make you feel more secure and allow you to enter the world of laser engraving machines. These laser safety sets and instructions will provide information on how to use the engraver safely and reduce the risk of fire.