The basic concept of CO2 laser tube

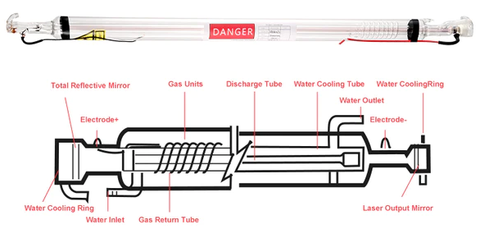

CO2 laser tube is a gas laser device that realizes laser output by the jump between the excited state energy levels of CO2 molecules.It is composed of a closed glass tube, filled with CO2, nitrogen, neon, and helium and other gases, equipped with a high reflectivity output mirror and semi-reflectivity mirror at both ends, forming the laser tube that is essential for operation. Additionally, laser replacement parts may be needed over time to maintain performance. When using an american laser engraver with a CO2 laser tube, this setup allows for precision and high-power output.

The working principle of CO2 laser tube

When the high-frequency electric field enters the CO2 laser tube, the excitation of gas molecules in the energy level changes. After many reflections between the mirrors, it will be issued through the output mirror laser beam. The laser wavelength of the CO2 laser tube is 10.6um, which is one of the lasers with the largest power available at present. American laser engraver technology takes advantage of this powerful output for various engraving applications, with laser replacement parts available to maintain efficiency.

The application fields of CO2 laser tube

1. Industrial processing field: CO2 laser tubes can be used for cutting, punching, welding, marking and other industrial processing fields. It has the advantages of fast cutting speed, large cutting depth and high processing precision, and is widely used in the precision processing of metal and non-metal materials.

2. Medical cosmetology field: CO2 laser tubes can be used in the field of medical cosmetology to remove acne, mole, spot, skin rejuvenation and so on. It has the advantages of controllable depth of action, remarkable therapeutic effect, safety and reliability, and so on, so it has been widely used in medical cosmetology industry.

3. Scientific research: CO2 laser tubes can also be used in scientific research in the field of atomic physics experiments, spectral technology, laser guidance and so on. The advantages of its laser power, single wavelength, stable work, etc., make it has a wide range of application value in the field of scientific research.

CO2 laser tube lifespan

CO2 laser tube is one of the most core parts of a cutting laser machine for engraving, which is an important component to convert electrical energy into laser energy. Generally speaking, CO2 laser tube lifespan depends on its frequency of use and maintenance, but most of the CO2 laser tube's lifetime is about 5000-9000 hours. If properly used and maintained, the life of a CO2 laser tube in an American laser engraving machine can be extended to more than 10,000 hours. If not properly maintained, the life of the CO2 laser tube may be less than 5000 hours, requiring laser replacement parts for continued operation.

Common Problems and Causes of CO2 Laser Tubes

CO2 laser tubes are a necessity in laser cutting, laser marking, and other industries, and their common problems are also the focus of the industry. The following lists some common problems and reasons for CO2 laser tubes in an american laser engraver:

1. Poor laser beam quality

The quality of the laser beam is an important factor affecting the accuracy of laser processing, if the laser beam quality is poor, there will be processed products with inaccurate dimensions, surface roughness and other problems. The reasons for this include impure working gas, contamination of the optical path, and aging of optical components.

2. Unstable beam

Unstable beam easily leads to parts size not maintaining, tool jitter, molding products' surface not being smooth, and other problems. The causes are mainly the loss of reflectivity of the laser tube wall mirror and poor alignment of the optical path. In such cases, replacing laser replacement parts can help restore optimal performance.

3. Laser power drop

Laser power decline refers to the laser output power is weakened or unstable, and its common problems include processing quality degradation, processing speed slowdown and so on. The reason may be the aging of the laser tube, co2 laser tube power supply voltage instability, poor cooling of the laser tube.

CO2 Laser Tube Troubleshooting

1. Poor quality of the laser beam

(1) Analyze the purity of the gas to ensure that the purity of the working gas in the laser tube meets the requirements;

(2) Clean the optical path and optical components to ensure that their surfaces are free of stains and wear;

(3) Replace the aging optical components.

2. Beam instability

(1) Adjust the alignment of the optical path to ensure that the axis of the optical path and the co2 laser tube axis;

(2) Clean the lens to avoid contamination resulting in beam instability;

(3) Regularly check the mirror reflectivity of the inner wall of the laser tubes to confirm whether it is lost.

3. Power drop problem

(1) Replace the badly aged co2 laser tube to ensure that it meets the required production date;

(2) Check whether the power supply voltage is stable to ensure that it is within the operating range;

(3) Regular cooling maintenance of the co2 laser tube, cleaning the cooling water circuit.

Maintenance Precautions

1. Avoid dust entering the CO2 laser tube, the surface of the laser tube needs to be cleaned regularly.

2. Replace the cooling water of the CO2 laser tube regularly and keep the water quality clean.

3. Adjust the cutting parameters of the cutting laser machine to avoid the working environment temperature is too high or too low.

4. Avoid using the cutting laser machine in high temperature environment, the temperature is too high may damage the laser tube.

5. Maintain the normal use of cutting laser machine environment, avoid vibration or violent shaking.

Methods to extend the co2 laser tube lifespan

1. Adjust the cutting parameters: the cutting temperature should not be too high, the speed should not be too fast, adjust the appropriate laser power and speed, can effectively extend the CO2 laser tube lifespan.

2. pay attention to maintenance: regular cleaning, replacement of cooling water and other maintenance operations is also an effective way to extend the lifespan.

3. maintain the use of the environment: maintain the normal use of the equipment environment, reduce the impact of external factors on the equipment, can also effectively extend the CO2 laser tube lifetime.

Monport CO2 laser tube has some advantages over traditional lasers, mainly including:

1. High power density: Monport CO2 laser tubes are capable of delivering high power density laser beams, which are suitable for many applications that require high energy density.

2. High Efficiency: Monport CO2 laser tubes typically have higher energy conversion efficiencies than other types of lasers, allowing for more efficient conversion of electrical energy into laser energy.

3. Long lifespan: Monport CO2 laser tubes usually have a long lifespan and good stability, capable of continuous and stable laser output.

4. Scale production: Compared to other types of lasers, Monport CO2 laser tubes have a high scale production capacity and can meet the needs of mass production.

Overall, Monport CO2 laser tubes have the advantages of high energy density, high efficiency, long life, and large-scale production, and are suitable for many different industrial and scientific applications. The reliability of American laser engraving machine systems ensures high-quality results and durability over time, with laser replacement parts available to maintain peak performance.

Enhance Your Metal Engraving with Monport Black Laser Marking Spray

Monport black laser marking spray is designed to provide sharp, high-contrast markings on a variety of metals, including aluminum, brass, and stainless steel. When used with CO2 laser engraving machines, this black laser marking spray ensures a smooth, even application that delivers long-lasting, permanent marks. The quick-drying formula of this spray helps maintain a fast-paced workflow, allowing the markings to dry in just minutes. With its easy-to-use design, Monport black laser marking spray creates professional-grade results for any metal engraving project. Whether you’re customizing tools, jewelry, or industrial parts, this black laser marking spray will ensure your creations stand out with exceptional precision and clarity.

Use code BESTMP10 at checkout – Click here to shop now!