Introduction

In the competitive landscape of laser engraving, where precision is paramount, the quest for clarity becomes a pivotal battleground. Amidst the array of options, the OMTech Polar emerges as a formidable contender, renowned for its precision and reliability. However, in the quest for optimal performance, one often overlooked aspect is the meticulous cleaning of the lens. Today, we delve into this crucial maintenance task, focusing on how to clean the lens on OMTech Polar, while also comparing its efficacy against competitors in the market. Join us in this exploration as we uncover the secrets to maintaining pristine clarity and highlighting the Monport laser engraver lens amidst its rivals.

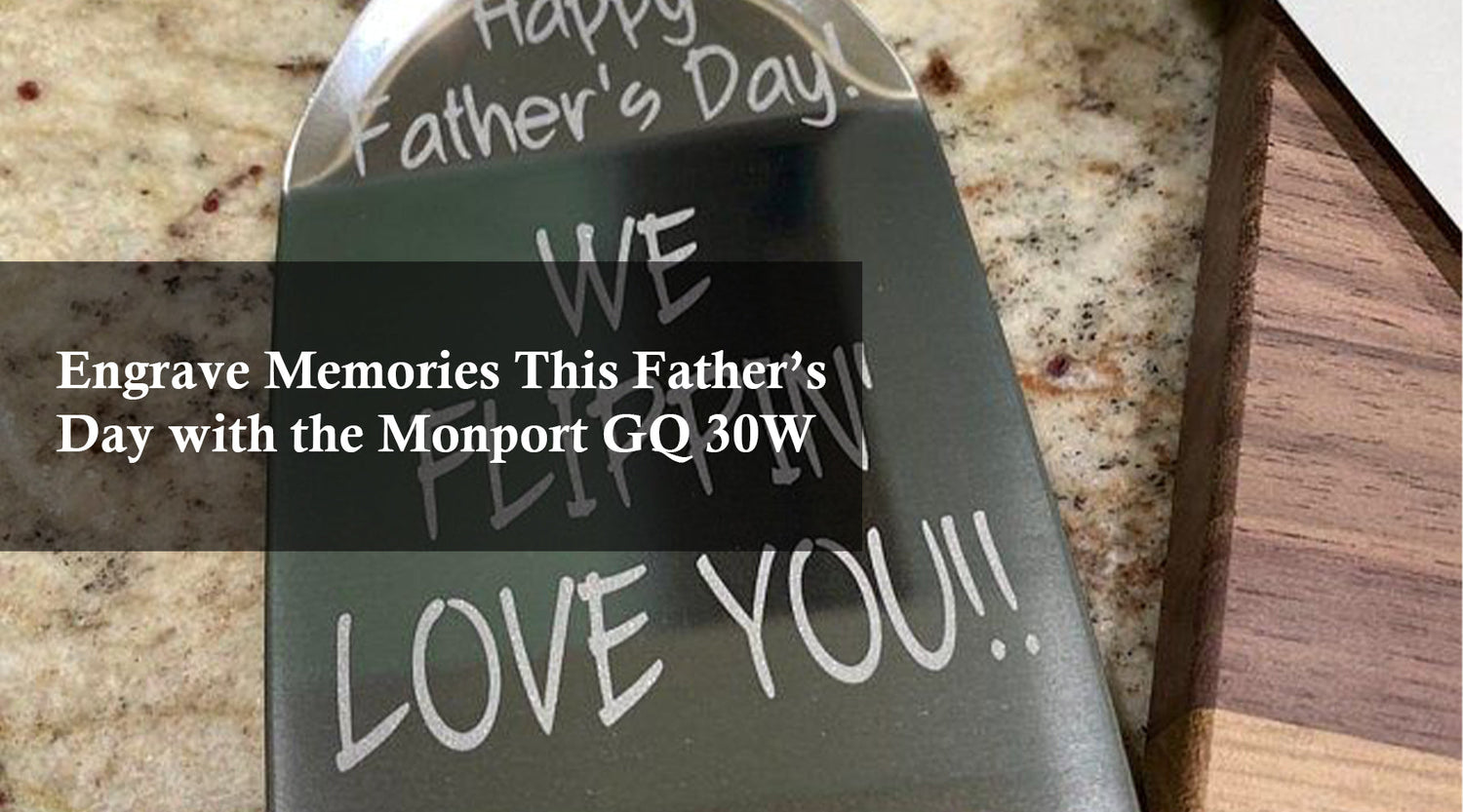

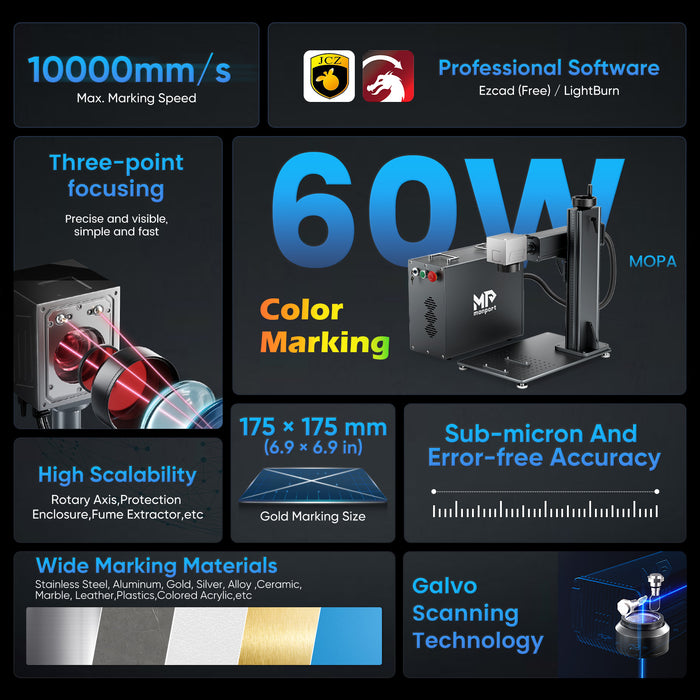

Monport GPro 60W Split MOPA Fiber Laser Engraver & Marking Machine With Manual Focus

Lens Quality Comparison: Monport vs. Competitors

The lens quality is one of the key factors that distinguish Monport from its competitors. Monport takes pride in its superior lens technology, offering exceptional performance and durability. In comparison with other brands, Monport lenses have consistently outperformed, delivering sharp and precise engraving results. The clarity and accuracy provided by Monport lenses leave little to be desired, making them a popular choice among professionals in the industry.

Monport F-theta M52 200mm*200mm Replacement Optical Scanning Lens

The Monport F-theta M52 200mm200mm Replacement Optical Scanning Lens for Fiber Laser Engraver is specifically designed for fiber laser engraving machines. This high-quality lens offers a generous 200mm200mm scanning area, allowing for larger engravings without compromising on details. The lens boasts excellent heat resistance, ensuring optimal performance even during extended use. Monport has carefully engineered this lens to deliver outstanding engraving results and withstand the rigors of daily operations.

Monport F-theta M52 200mm*200mm Replacement Optical Scanning Lens for Fiber Laser Engraver

Monport GPro 60W Split MOPA Fiber Laser Engraver & Marking Machine With Manual Focus

Another noteworthy product from Monport is the Monport GPro 60W Split MOPA Fiber Laser Engraver & Marking Machine With Manual Focus. This machine combines power and precision, enabling users to accomplish a wide range of engraving tasks with ease. The integrated manual focus feature further enhances the control and versatility of the machine. The lens used in this model is of the same exceptional quality as other Monport lenses, guaranteeing unmatched engraving results.

Cleaning the Lens on a Monport Machine

To maintain the optimal performance of your Monport laser engraving machine, it is essential to clean the lens regularly. Follow these simple steps to ensure a clean lens:

- Gather the necessary supplies: You will need a clean lint-free cloth, lens cleaner solution specifically designed for optical lenses, and a blower brush.

- Power off the machine: Before cleaning the lens, make sure to turn off the machine and unplug it from the power source for safety.

- Remove the lens: Carefully detach the lens from the engraving head following the manufacturer's instructions.

- Use a blower brush: Gently remove any loose dirt or debris from the lens surface using a blower brush. Be cautious not to apply too much pressure to avoid scratching the lens.

- Apply the cleaning solution: Dampen a clean lint-free cloth with the lens cleaner solution. Ensure the cloth is not saturated, as excessive moisture can damage the lens.

- Wipe the lens: Using the damp cloth, gently wipe the lens surface in a circular motion. Remove any smudges or fingerprints that may have accumulated over time.

- Dry the lens: Once you have cleaned the lens, allow it to air dry or use a dry lint-free cloth to carefully remove any remaining moisture. Ensure the lens is completely dry before reattaching it to the engraving head.

Frequently Asked Questions (FAQs)

Q: Is it necessary to clean the lens often?

A: Yes, regular cleaning of the lens is crucial for maintaining optimal engraving quality.

Q: Can I use any lens cleaner solution?

A: It is advisable to use a lens cleaner solution specifically designed for optical lenses to avoid damaging the lens.

Q: How often should I replace the lens on my Monport machine?

A: The frequency of lens replacement depends on various factors such as usage and maintenance. If you notice a decline in engraving quality, it may be time to consider replacing the lens.

Takeaways

- Monport offers superior lens quality compared to its competitors.

- Regular cleaning of the lens is necessary to maintain optimal engraving quality.

- Monport F-theta M52 and Monport GPro models provide exceptional engraving results.

- Use a lens cleaner solution and a lint-free cloth to clean the lens.

- Consider replacing the lens if engraving quality declines.

Conclusion

When it comes to laser engraving, the quality of the lens is paramount. Monport stands out among its competitors, offering top-of-the-line lens technology that ensures precise and accurate engraving results. With the Monport F-theta M52 200mm*200mm Replacement Optical Scanning Lens and the Monport GPro 60W Split MOPA Fiber Laser Engraver & Marking Machine With Manual Focus, professionals in the industry can achieve outstanding engraving quality. By following the proper cleaning procedures, users can prolong the life of the lens and maintain consistent engraving performance.

Unlock Crystal-Clear Precision with Monport

Don’t let dust or low-quality lenses dull your engraving results. Choose Monport for industry-leading lens technology, effortless maintenance, and precision that lasts. Whether you're upgrading your setup or simply need a replacement lens, Monport delivers unmatched clarity and durability—project after project.

Explore Monport Lenses & Machines Now — because your work deserves nothing but the sharpest detail.