Laser marking on paper opens up a world of creative possibilities, from custom stationery and invitations to intricate artwork and packaging designs. Black laser marking spray can enhance the contrast and precision of the markings.With the right settings and techniques, the OMTech laser wood engraving machine can achieve stunning results on various types of paper, making it one of the best laser engravers for wood.In this guide, we'll explore the essential OMTech settings and techniques for laser marking paper, empowering you to unleash your creativity with precision and finesse using the OMTech laser engraver.

Choosing the Right Paper

Before diving into laser marking, it's crucial to select the appropriate paper for your project. Different types of paper have varying densities, coatings, and compositions, which can affect the engraving results. Opt for high-quality paper with minimal coatings or additives for optimal performance with the OMTech laser engraver. Black laser marking spray can be used to enhance the contrast and precision on certain paper types. Experiment with different paper weights and textures to find the perfect match for your desired aesthetic.

OMTech Laser Settings

When laser marking paper with the OMTech laser engraver, the following settings serve as a starting point for achieving optimal results:

1. Power: Begin with a low to medium power setting, typically ranging from 5% to 20% power, depending on the thickness and composition of the paper. Higher power settings can lead to excessive burning or scorching, while lower power settings may result in incomplete marking. Black laser marking spray can be applied to improve the contrast and precision at lower power settings.

2. Speed: Adjust the engraving speed to achieve the desired depth of marking without damaging the paper. Start with a moderate speed setting, such as 1000 mm/s, and fine-tune as needed based on the clarity and depth of the mark.

3. Resolution: Choose a high resolution setting to ensure crisp, detailed engraving. A resolution of 300 to 600 DPI is typically suitable for capturing intricate designs and text with the OMTech laser engraver. Black laser marking spray can help achieve cleaner, more defined engravings.

4. Scan Gap: The scan gap determines the spacing between individual laser passes and can influence the overall quality of the engraving. A smaller scan gap, such as 0.05 mm, results in smoother and more uniform marking, making the OMTech laser engraver ideal for detailed projects. Black laser marking spray ensures consistent quality throughout the engraving process.

Techniques for Laser Marking Paper

In addition to adjusting laser settings, employing these techniques can enhance the quality and versatility of your work with the OMTech laser engraver:

-

Masking: Applying a masking material, such as masking tape or transfer tape, to the surface of the paper can protect delicate areas from scorching or burning during engraving. After engraving, simply remove the masking material to reveal the crisp, clean mark underneath.

-

Multiple Passes: For deeper or more pronounced marking, consider running multiple passes with the laser at lower power settings. This allows the laser to gradually penetrate the paper without causing excessive heat buildup or damage.

-

Testing and Iteration: Conduct test engravings on sample pieces of paper to fine-tune settings for the OMTech laser engraver. Keep a log of successful settings for future reference and experimentation.

In conclusion, mastering laser marking on paper with OMTech laser engraving machines is a rewarding endeavor that opens up endless creative possibilities. By selecting the right paper, adjusting laser settings, and employing proven techniques, you can achieve stunning results that elevate your projects to new heights. Whether you're personalizing invitations, creating custom artwork, or designing intricate packaging, OMTech provides the tools and support you need to bring your vision to life with precision and finesse. Experiment, explore, and unleash your creativity with OMTech laser marking on paper. Black laser marking spray can enhance the contrast and precision for achieving the best results.

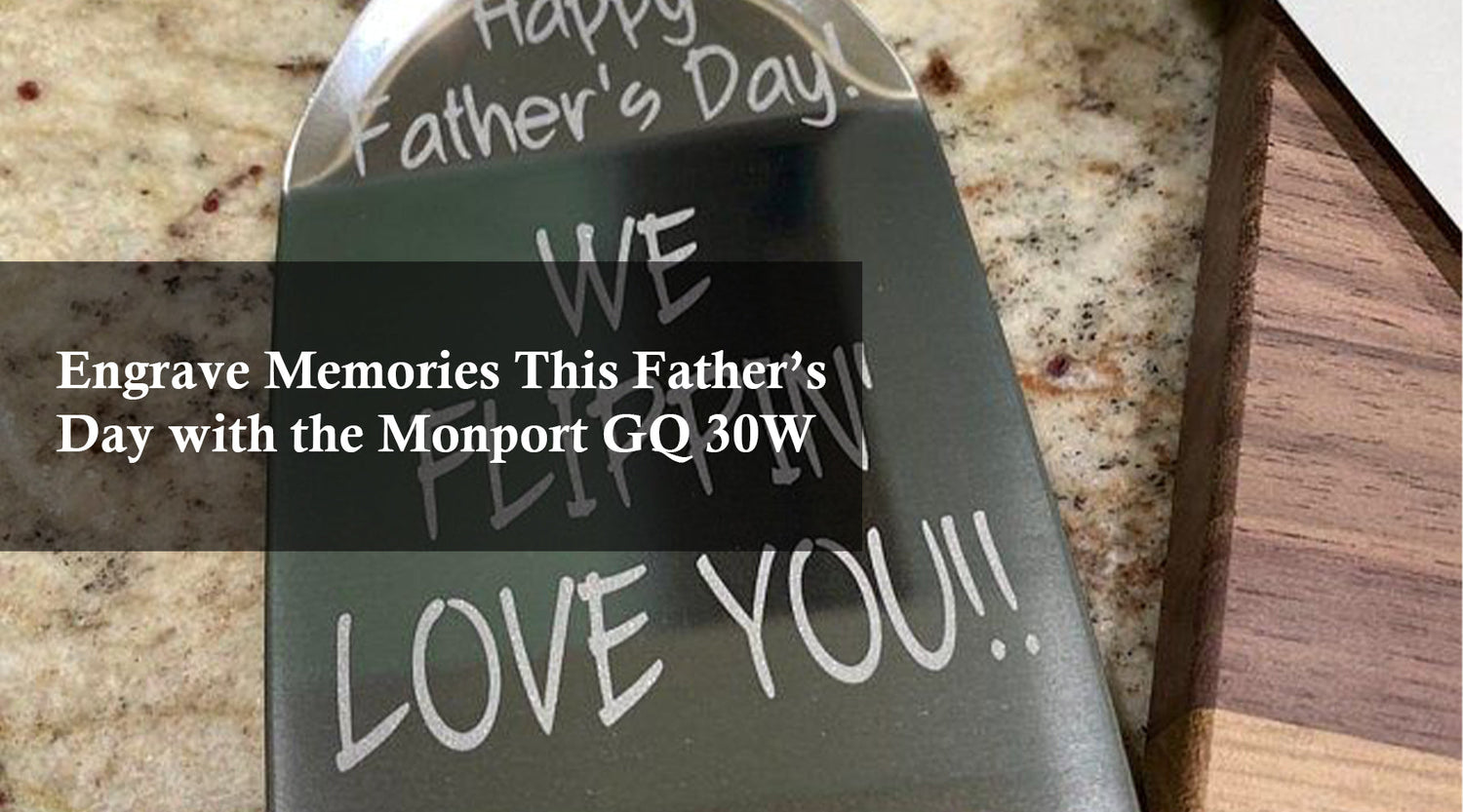

If you're looking for a high-quality laser wood engraving machine better than OMTech with high-quality laser cutting solutions without breaking the bank, all while enjoying unparalleled support and assistance to ensure a seamless experience - Choose Monport! Let's explore why Monport stands out as the best laser engraver for wood, providing both value and reliability to users across the board.

Unlocking Superiority of Monport K40 CO2 Laser Engraver Over OMTech for Laser Marking Paper

When it comes to laser wood engraving paper, precision, speed, and versatility are paramount for achieving flawless results. In this competitive landscape, Monport's K40 CO2 Laser Engraver stands out as a superior choice compared to OMTech, offering a range of exceptional features that elevate the laser wood engraving experience to new heights. Let's delve into why Monport's K40 CO2 Laser Engraver reigns supreme in the realm of laser wood engraving, boasting exceptional speed, precision, and innovative features that set it apart from the competition. Black laser marking spray can further enhance the precision and contrast for achieving the best engraving results.

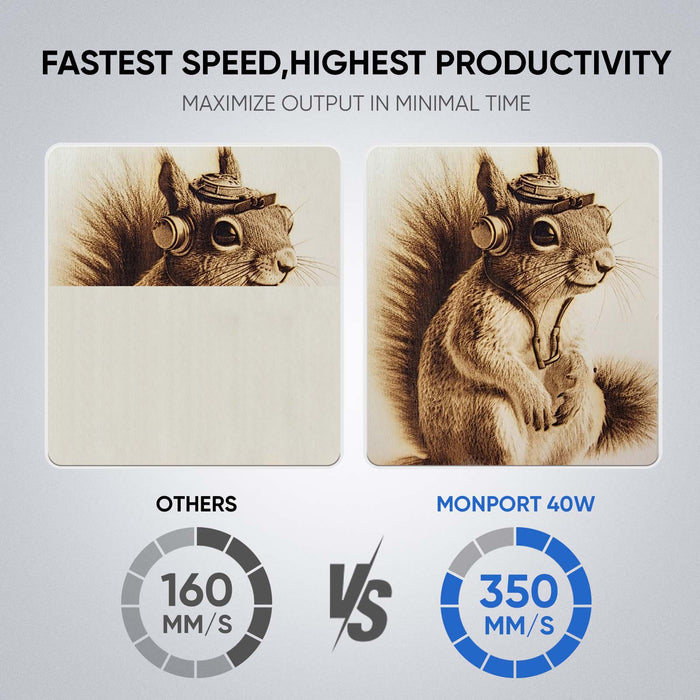

Exceptional Speed and Precision

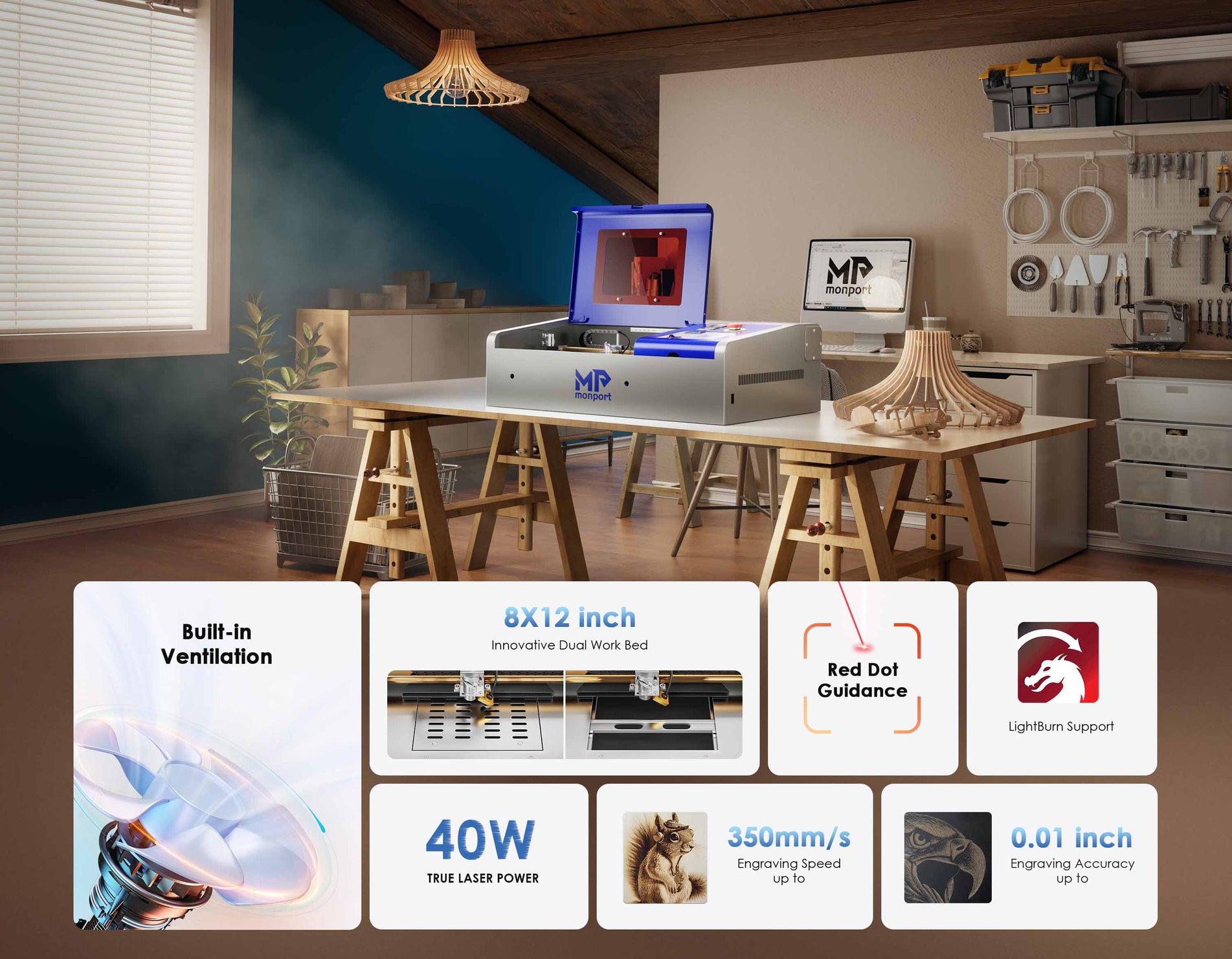

Monport's K40 CO2 Laser Engraver is engineered for unparalleled speed and precision, ensuring swift and accurate laser wood engraving on paper. With an impressive engraving speed of up to 350mm/s and an engraving accuracy of 0.01 inches, this desktop engraving machine delivers precise results with remarkable efficiency. Whether you're engraving intricate designs or fine text, the Monport K40 CO2 Laser Engraver guarantees crisp, clean markings on paper with every pass. Black laser marking spray can enhance the clarity and contrast of the markings on paper for exceptional results.

Lightburn Compatibility

Equipped with an upgraded control board, the Monport K40 CO2 Laser Engraver ensures seamless compatibility with Lightburn – the industry-leading software renowned for its versatility and ease of use. With Lightburn at your disposal, you can unleash your creativity and explore a multitude of design possibilities, from intricate patterns to elaborate artwork, all with unparalleled precision and control.

Built-in Air Assist

Monport's K40 CO2 Laser Engraver features a built-in air assist system that enhances engraving precision and minimizes carbonization effects when marking paper. By providing a steady stream of air to the engraving area, the air assist system ensures that the final artwork is clear, clean, and free from imperfections. Say goodbye to smudges and smears – with Monport's K40 CO2 Laser Engraver, every engraving on paper is a masterpiece.

Machine Component Upgrade

The Monport K40 CO2 Laser Engraver is equipped with a suite of enhanced features, including a 19mm Adjustable Laser Head, Professional-Grade Metal Rails, and a top-tier mirror holder. These upgrades not only enhance the durability and longevity of the machine but also ensure a refined engraving experience for users. With Monport, you can trust that every engraving on paper is executed with precision and finesse, thanks to these advanced components.

Red Dot Guidance

Never miss the mark with Monport's Red Dot Guidance feature, mounted on the laser head to illustrate the laser's path with pinpoint accuracy. Whether you're lining up cuts or positioning engravings on paper, the red dot guidance system provides visual assistance, ensuring that your markings are precisely aligned every time. With Monport, precision is not just a promise – it's a guarantee.

Innovative Dual Work Bed

Monport's K40 CO2 Laser Engraver comes with a dual work bed, offering two options for more possibilities in laser wood engraving. The stabilizer clamp secures irregularly shaped objects in place, while the vented level board caters to regular shapes, making every engraving project a breeze. With Monport's innovative dual work bed, you have the flexibility to tackle a wide range of paper-based projects with ease and efficiency.

Built-in Ventilation

Integrated fan to boost laser performance, improve ventilation, and reduce noise. The exhaust port helps to create a safe work environment, so you can vent the fumes to the outdoors. With Monport's built-in ventilation system, you can enjoy a comfortable and safe laser wood engraving experience, free from harmful fumes and excessive noise. Black laser marking spray can be used to improve the visibility and sharpness of the engravings, especially on darker materials.

In conclusion, Monport's K40 CO2 Laser Engraver surpasses OMTech in every aspect when it comes to laser marking paper. With exceptional speed, precision, and innovative features such as Lightburn compatibility, built-in air assist, and red dot guidance, Monport offers a superior engraving experience that guarantees flawless results on paper. Whether you're a hobbyist, artist, or professional, trust Monport's K40 CO2 Laser Engraver to bring your paper-based projects to life with unmatched precision and efficiency. In this guide, we'll explore the essential OMTech settings and techniques for laser marking paper, empowering you to unleash your creativity with precision and finesse. Visit Monport today!