The world of design and fabrication is constantly evolving, and 3D laser engraving has emerged as a powerful tool for both hobbyists and professionals. This technology takes lazer cutters to a new level, offering the ability to create intricate designs with depth and dimension through laser engraving 3D techniques. If you're curious about laser etching 3D and its possibilities, this comprehensive guide explores the technology behind laser cutters, 3d laser carving, and how they can revolutionize your creative endeavors engraved on leather, including laser etching 3D techniques, 3d laser cutting, and how the use of black laser marking spray can enhance your designs with sharp, high-contrast details. Many creators now rely on a 3d laser cutter to achieve consistent depth and accuracy.

What is 3D Laser Engraving?

While traditional laser engraving creates precise designs on a flat surface, laser etching 3D goes beyond that by introducing 3d laser carving depth control. It utilizes a computer-controlled laser beam to remove material layer by layer, gradually building a three-dimensional relief on the chosen surface using laser engraving 3D workflows. This allows for the creation of stunningly detailed and textured objects with depth, such as acrylic sheets for laser cutting that undergo 3d laser cutting to form complex contours. Designs can be further enhanced with black laser marking spray for added contrast when engraved on leather using a 3d laser cutter.

How Do Lazer Cutters Work?

Laser cutters are the machines that power laser etching 3D and modern 3d laser engraving systems. They function by focusing a high-powered laser beam onto a specific area of the material, vaporizing it and removing it with a pressurized air assist. By precisely controlling the laser beam's movement and power output, the 3d laser cutter can create intricate cuts and designs on various materials, including acrylic sheets for laser cutting. This process supports 3d laser cut production and detailed laser engraving 3D results when engraved on leather, especially with the help of black laser marking spray for enhanced contrast.

Materials Compatible with 3D Laser Engraving

The versatility of lazer cutters and 3d laser cutters is one of their greatest strengths. They can work with a wide range of non-metallic materials, including:

-

Wood

-

Acrylic

-

Leather

-

Glass

-

Fabric

-

Paper

-

Stone (with specific laser types)

This material compatibility opens doors to countless creative applications for 3d laser engraving, 3d laser carving, and precision 3d laser cutting, especially for acrylic sheets for laser cutting.

Benefits of Using a Lazer Cutter for 3D Engraving

-

High Precision: Lazer cutters offer exceptional accuracy, allowing for the creation of incredibly detailed 3d laser engraving and laser engraving 3D designs on acrylic sheets for laser cutting.

-

Versatility: These laser cut machines can work with a wide range of materials, including wood, acrylic sheets for laser cutting, leather, and even some plastics using 3d laser cutting methods.

-

Speed and Efficiency: Laser cutting is a fast and efficient process, allowing for the rapid creation of 3D engraved objects through 3d laser cut workflows, including complex acrylic sheets for laser cutting designs.

-

Design Flexibility: 3D design software provides limitless possibilities for creating unique and customized 3D models for engraving and 3d laser carving on acrylic sheets for laser cutting.

-

Minimal Waste: Laser cutting minimizes material waste compared to traditional carving techniques, especially when working with acrylic sheets for laser cutting using a 3d laser cutter.

Applications of 3D Laser Engraving

3d laser engraving has a wide range of applications across various industries and creative fields, especially where laser engraving 3D depth is required:

-

Product Prototyping: Create realistic and functional prototypes for product development with precise detail using 3d laser cutting and 3d laser carving.

-

Signage & Décor: Craft unique and eye-catching signage with 3D text, logos, or intricate designs produced through 3d laser cut techniques.

-

Jewelry & Accessories: Design and engrave personalized laser cut acrylic jewelry with intricate details using 3d laser engraving and laser engraving 3D processes.

-

Art & Design: Push the boundaries of artistic expression by creating 3D sculptures, reliefs, or mixed-media art pieces with depth using 3d laser carving.

-

Industrial Applications: Laser cutters and 3d laser cutters are used for precise marking, etching, and 3d laser engraving in electronics and medical device manufacturing.

Mastering the Craft: A Guide to 3D Laser Engraving with Lazer Cutters

While the possibilities with 3d laser engraving are exciting, achieving optimal results requires an understanding of the process and proper parameter settings. Here's a breakdown to guide you through laser engraving 3D and engraved on leather laser etching 3D workflows.

Machine Setup

-

Software: Ensure your lazer cutter or 3d laser cutter is connected to your computer and the compatible design software is installed (e.g., RDWorks, LightBurn).

-

Material Selection: Choose the material for your 3D engraved project, considering its thickness and compatibility with 3d laser cutting.

-

Artwork Preparation: Design your 3D artwork in a compatible software format (e.g., DXF, AI). Your design should consist of multiple layers, each representing a different depth level for 3d laser carving and final 3d laser cut output.

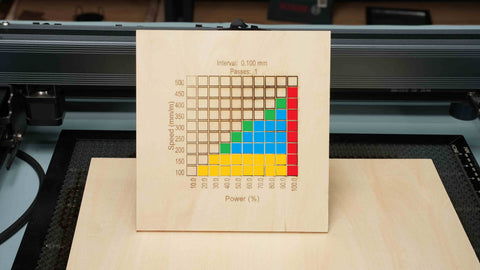

Parameter Settings for 3D Laser Engraving

-

Laser Power: Determines the intensity of the laser beam and engraving depth. Essential for controlled 3d laser engraving layers.

-

Scan Speed: Slower speeds allow deeper 3d laser carving, while faster speeds support lighter laser engraving 3D passes.

-

Pulse Frequency (Hz): Affects engraving detail and smoothness in 3d laser engraving.

-

Line Spacing: Controls texture quality in 3d laser cut engraving passes.

-

Focus Height: Ensures accuracy for 3d laser cutting and clean depth transitions.

Tips for Successful 3D Laser Engraving

-

Start with simple designs to learn 3d laser carving depth control

-

Experiment with parameters for optimized laser engraving 3D results

-

Test on scrap material before final 3d laser cut runs

-

Maintain proper ventilation when using a 3d laser cutter

FAQs

What is the difference between 3d laser engraving and 3d laser cutting?

3d laser engraving removes material gradually to create depth, while 3d laser cutting slices through material for full separation.

Can a 3d laser cutter handle both engraving and cutting?

Yes, a quality 3d laser cutter can perform 3d laser engraving, 3d laser carving, and 3d laser cut operations with proper settings.

Is laser engraving 3D suitable for beginners?

Laser engraving 3D is beginner-friendly with practice, especially when starting with simple 3d laser carving designs.

What materials work best for 3d laser carving?

Wood, acrylic, and leather respond well to 3d laser carving and laser engraving 3D techniques.

Do I need special software for 3d laser cutting?

Yes, design software like LightBurn or RDWorks is required to control 3d laser cutting and 3d laser engraving processes.

Unlock a World of Creative Possibilities

Laser etching plastic is more than just a technology; it's a portal to a world of boundless creativity powered by 3d laser engraving and 3d laser cutting. With its ability to transform flat surfaces into captivating 3D designs, laser etching plastic empowers you to bring your artistic vision to life using laser engraving 3D methods. The Monport 100W CO2 Laser Engraver is your perfect partner in this exciting exploration, offering the precision and power needed to achieve stunning results with 3d laser carving, especially when engraved on leather with black laser marking spray.

Visit the Monport website today to learn more about the Monport 100W CO2 Laser Engraver and its 3d laser cutter capabilities. Explore resources to master 3d laser engraving, 3d laser cut design, and professional 3d laser cutting techniques.

-

Take your creations to the next level with the Monport 100W CO2 Laser Engraver

- Ready to start engraving? Use code BESTMP10 at checkout – Click here to shop now!

Explore Monport’s site to dive deeper into laser etching 3D tutorials, 3d laser carving ideas, and accessories. Don’t just design—bring your laser etching plastic ideas to life with 3d laser engraving.