Laser engraving has revolutionized the way we approach metalwork, allowing hobbyists and professionals alike to achieve intricate designs and precision cuts with ease. One of the most effective tools for this purpose is the metal fiber laser cutting machine. In this article, we will explore how to DIY engrave metal and provide a comprehensive guide to starting your laser engraving journey using Monport fiber laser engravers. Many beginners often ask, how do i engrave metal in the easiest way possible, and this guide will cover just that.

Introduction to DIY Engrave Metal

Learning how to DIY engrave metal can open up a world of creative and practical possibilities. Whether you're looking to personalize jewelry, create custom signage, or produce detailed artwork, a metal fiber laser cutting machine is an invaluable tool. These machines offer unmatched speed, precision, and flexibility, making them ideal for a wide range of applications. If you’ve ever wondered, how do i engrave metal with professional results, using the right machine is the answer.

Getting Started with Monport Fiber Laser Engravers

Choosing the Right Equipment

To successfully DIY engrave metal, selecting the right laser engraver is crucial. The Monport 60W JPT MOPA fiber laser marking machine is a top choice, offering several features that make it ideal for both beginners and advanced users. This machine stands out due to its adjustable pulse frequency and width, enabling vibrant color marking on stainless steel and high-contrast engraving on anodized aluminum. For anyone asking, how do i engrave metal at home, this machine provides the perfect solution.

Key Features of Monport's Fiber Laser Engravers

Monport GI 60W Integrated MOPA Fiber Laser Engraver & Marking Machine with Electric Lifting

- Full Color Marking: The adjustable pulse frequency and width allow for vibrant color markings, particularly on stainless steel, enhancing the aesthetic appeal of your projects.

- High Precision: With a precision cut of up to 0.05mm per pass and accuracy to ±0.1 micron, Monport's fiber laser ensures detailed and accurate engravings.

- Electric Lifting Focus: The concealed lifting motor ensures precise focusing, making it easy for beginners to achieve high-quality results.

- Integrated Innovative Design: The machine's lighter weight, smaller size, and user-friendly design make it easy to use without compromising on performance.

- LightBurn Compatibility: The machine comes with EZCad 2.0 software and is fully compatible with LightBurn software, providing a seamless user experience and extensive customization options.

- Industry-Leading Heat Dissipation: Built-in air cooling and unique side panel openings improve heat dissipation, maintaining peak performance.

Setting Up Your Monport Laser Engraver

- Unboxing and Assembly: Carefully unbox your Monport laser engraver and follow the assembly instructions. Ensure all components are properly installed and secured.

- Connecting the Device: Connect the laser engraver to your computer using the provided USB cable. Ensure the connection is stable and that the machine is recognized by your computer.

- Installing Software: Download and install EZCad 2.0 or LightBurn software. These programs will be your primary tools for designing and managing your engraving projects.

How to DIY Engrave Metal

Preparing Your Design

- Selecting Your Design: Choose a design or create your own using graphic design software. Ensure the design is high quality and suitable for engraving.

- Importing the Design: Import the design into EZCad 2.0 or LightBurn. Adjust the size and position of the design to fit the metal surface you will be engraving.

-

Setting Parameters: Configure the laser settings such as power, speed, and frequency. These settings will vary depending on the type of metal and the desired engraving depth and quality. Anyone wondering, how do i engrave metal with different finishes will find parameter control essential.

Preparing the Metal

- Cleaning the Surface: Clean the metal surface to remove any dirt, grease, or residue. A clean surface ensures a better engraving result.

- Securing the Metal: Place the metal securely on the workbed of the laser engraver. Ensure it is firmly held in place to prevent movement during engraving.

Engraving Process

- Focusing the Laser: Use the electric lifting focus feature to precisely focus the laser on the metal surface. This step is crucial for achieving a clear and accurate engraving.

- Starting the Engraving: Begin the engraving process by running a test on a small area or scrap piece of metal. This allows you to fine-tune the settings for optimal results.

- Monitoring the Process: Keep an eye on the engraving process to ensure everything runs smoothly. Make any necessary adjustments to the settings if needed.

Post-Engraving Finishing

After the engraving is complete, carefully remove the metal piece from the machine. Clean off any residue and inspect the engraving for quality. If needed, polish the engraved area to enhance the appearance.

Q&A about Monport Fiber Laser Engravers

What Makes Monport Fiber Laser Engravers Stand Out?

Monport fiber laser engravers are known for their precision, speed, and flexibility. The 60W JPT MOPA model offers unique features like full color marking on stainless steel and high-contrast engraving on anodized aluminum, making it a versatile choice for various projects.

How Beginner-Friendly Are Monport Laser Engravers?

Monport's laser engravers are designed with beginners in mind, featuring user-friendly controls, comprehensive software compatibility, and an electric lifting focus system that simplifies the engraving process.

Can Monport Laser Engravers Handle Large Projects?

Yes, Monport laser engravers are suitable for both small and large projects. The integrated innovative design allows for efficient and accurate engraving, regardless of the project size.

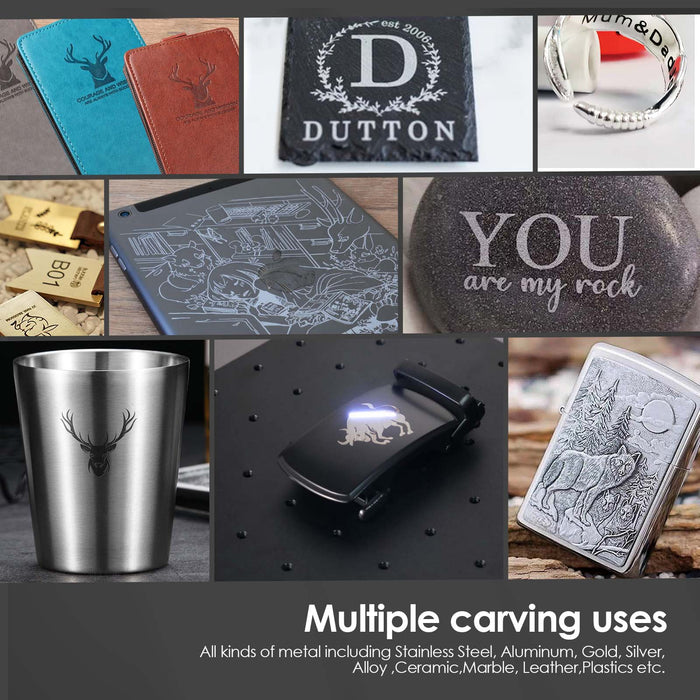

What Materials Can Be Engraved with Monport Fiber Lasers?

Monport fiber lasers can engrave a variety of metals, including stainless steel, aluminum, and more. The adjustable settings allow for customization to achieve the desired results on different materials.

How Does Heat Dissipation Affect Performance?

Effective heat dissipation is crucial for maintaining the performance and longevity of the laser engraver. Monport's built-in air cooling and side panel openings enhance heat dissipation, ensuring the machine operates at peak performance.

Key Takeaways

- Learning how to DIY engrave metal can unlock endless creative possibilities, from personalized gifts to intricate artwork.

- The Monport 60W JPT MOPA fiber laser marking machine is an excellent tool for metal engraving, offering precision, speed, and flexibility.

- Proper setup, preparation, and practice are essential for achieving high-quality results in metal engraving.

- Utilizing the features of Monport laser engravers, such as electric lifting focus and software compatibility, can significantly enhance your engraving projects.

Conclusion

Metal engraving with a metal fiber laser cutting machine offers a precise and versatile method for creating detailed designs on various metal surfaces. By understanding how to DIY engrave metal and leveraging the advanced features of Monport fiber laser engravers, you can achieve professional-quality results with ease. The question, how do i engrave metal, is no longer a challenge once you have the right tools. For more information and to explore the full range of Monport laser engravers, visit Monportlaser.com.

Read More: A Comprehensive Guide to Metal Marking and Metal Cutter Machines