Laser cutting has revolutionized the manufacturing industry, offering precise and efficient cutting solutions for a wide range of materials. While laser cutters are commonly associated with cutting wood, acrylic, and other non-metallic materials, many wonder: can laser cutters cut metal? In this article, we'll explore what type of laser is used to cut metal and limitations of laser cutting metal, including choosing the right 100 watt fiber laser for your metal projects.

Understanding Laser Cutting

Laser cutting is a process that uses a high-powered laser beam to melt, burn, or vaporize materials along a predetermined path. The intense heat generated by the laser beam allows for precise cutting with minimal material waste. Laser cutters are equipped with computer-controlled mirrors and lenses that guide the laser beam, enabling intricate and accurate cuts. But what type of laser is used to cut metal?

Types of Metal Suitable for Laser Cutting

While laser cutting can cut metal, the process is typically limited to specific metals with favorable properties. Here are some of the most common types:

-

Mild Steel: Known for its low melting point and ease of cutting, mild steel is a popular and cost-effective choice.

-

Stainless Steel: Valued for corrosion resistance and strength, but it requires higher laser power and refined technique to avoid discoloration and burring.

-

Aluminum: Lightweight and versatile, but due to its high thermal conductivity, it needs precise adjustments to achieve clean results.

If you're wondering can laser cut metal include all of these types—yes, but only with the right machine and settings, particularly when using high-powered fiber lasers.

Limitations of Laser Cutting Metal

Despite its advantages, laser cutting metal has several limitations:

-

Thickness: While laser cutters can cut metal, the ability to handle thicker sheets depends on the machine’s wattage. Thicker metals require more power and time.

-

Material Composition: Inconsistent metal composition, like impurities or alloys, can reduce cut quality and require laser parameter adjustments.

-

Reflectivity: Metals such as copper or brass reflect laser energy, making them harder to cut with CO₂ lasers. Fiber lasers are more effective in these cases.

So, can laser cut metal be done without limitations? Yes—with the right machine, like a high-wattage fiber laser, and a good understanding of the material properties.

Unleash Precision and Creativity with the Monport GPro 100W Split MOPA Fiber Laser Engraver

Unlock Big Savings at Monport Laser! Use code BESTMP10 at checkout for an exclusive discount – Click here to shop now!

ReadMore : Can a Laser Cutter Cut Metal? Exploring Stainless Steel Marking

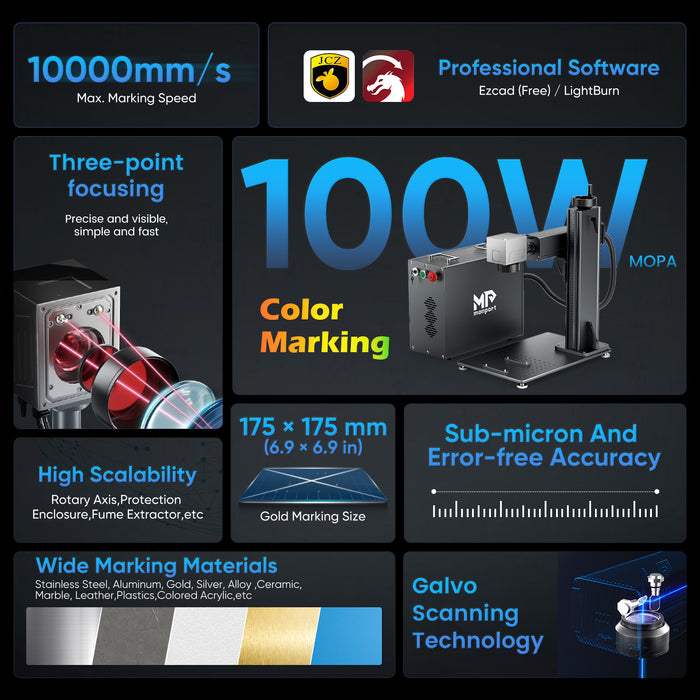

Meet the Monport GPro 100W Split MOPA Fiber Laser Engraver, a powerhouse machine designed to exceed your expectations and elevate your marking capabilities to new heights. With its powerful laser core, advanced marking controller, and host of innovative features, it's no wonder why this machine is considered the best in its class.

Powerful Laser Core & High-Performance Marking Controller

At its core, the Monport GPro 100W features a robust MOPA laser delivering a full 100 watts of power. Paired with the JCZ marking controller, this system pushes past typical limitations, allowing intricate engraving and clean metal cutting with ease—proof that laser machines can laser cut metal when properly configured.

Versatile Laser Marking Capabilities

With adjustable frequency (1-3000kHz) and pulse width (2-500ns), the Monport GPro 100W offers unparalleled versatility in laser marking. From vibrant stainless steel markings to intricate designs on plastic buttons, this machine enables a wide range of applications with rich and precise visual effects. Say goodbye to limitations and unleash your creativity like never before.

Premium Galvanometer and Enhanced Focus

The Monport GPro 100W is equipped with a high-end Sino-Galvo SG7110 galvanometer, ensuring exceptional stability, precise positioning, and rapid marking speed. Combined with three-point red light alignment for easy focusing, this machine allows for precise and efficient marking, even on complex surfaces. With enhanced focus and precision, you can confidently tackle any marking project with ease.

Enhanced Security and Versatile Operating Software

Safety is paramount, which is why the Monport GPro 100W features enhanced security features such as access keys and emergency stop buttons. Additionally, its compatibility with EzCad2 and LightBurn software ensures seamless operation on both Windows and Mac systems, providing flexibility and convenience for users.

Quartz FTheta Field Lenses for Precision

To further enhance precision and stability, the Monport GPro 100W utilizes quartz material FTheta field lenses. These lenses are tailored for high-power laser processing, ensuring accuracy and robust interference resistance. With these lenses, you can trust that your markings will be precise and consistent, every time.

Conclusion

While laser cutters are widely used for non-metallic materials, the ability to laser cut metal is well within reach—especially when using the right equipment. So, can laser cut metal be a part of your workshop or production process? With machines like the Monport GPro 100W Split MOPA Fiber Laser, the answer is a resounding yes.

By understanding metal properties, laser technology, and limitations, you can confidently incorporate laser cutting into your workflow and deliver precise, professional results every time.