Introduction

While CO2 lasers have long been a dominant force in this realm, many users grapple with the question: Can OMTech CO2 lasers achieve metal marking or engraving?

The answer is not typically. CO2 laser machines excel at engraving and cutting non-metals like wood, acrylic, leather, and glass. However, their wavelength isn't ideal for processing metals effectively. This is because CO2 laser machines operate at a wavelength (typically around 10.6 micrometers) that metals tend to reflect rather than absorb. This reflection hinders the laser machines' ability to create a permanent mark on the metal surface. For metal marking and engraving, a different technology comes into play – fiber laser machines.

In this blog post, we'll explore the limitations of CO2 lasers for metalwork and introduce the Monport metal engraver GA Upgraded 60W Integrated MOPA Fiber Laser Engraver & Marking Machine with Auto Focus. This innovative machine leverages fiber laser machines technology to deliver exceptional metal marking and engraving capabilities. We'll also delve into the advantages of MOPA technology for metal applications and conclude with a comparison table to help you choose the right laser machines for your needs.

GA Upgraded 60W Integrated MOPA Fiber Laser Engraver & Marking Machine with Auto Focus

CO2 vs. Fiber Lasers: Understanding the Limitations of CO2 for Metal Marking

OMTech CO2 lasers utilize a carbon dioxide gas mixture to generate a laser beam with a wavelength of around 10.6 micrometers. This wavelength is efficiently absorbed by organic materials, allowing the laser to precisely vaporize or etch patterns and designs. However, metals tend to reflect this CO2 laser wavelength rather than absorb it. This reflection hinders the laser's ability to create a permanent mark on the metal surface.

While some techniques like using a laser bonding agent can achieve a temporary mark on certain metals with a CO2 laser, the results are often inconsistent and lack the depth and permanence desired for most applications.

Enter the Fiber Laser: A Powerful Solution for Metal Marking and Engraving

Fiber lasers, on the other hand, operate at a much shorter wavelength, typically around 1.06 micrometers. This shorter wavelength is readily absorbed by metals, making fiber lasers the preferred choice for permanent metal marking and engraving. The Monport metal engraver GA Upgraded 60W Integrated MOPA Fiber Laser Engraver & Marking Machine with Auto Focus leverages this technology to deliver exceptional results on various metals.

Here's a closer look at the advantages of fiber lasers for metal marking and engraving:

- Superior Absorption: As mentioned earlier, the shorter wavelength of fiber lasers ensures efficient absorption by metal surfaces, leading to clean, precise, and permanent marks.

- High-Speed Marking: Fiber lasers boast significantly faster marking speeds compared to CO2 lasers, making them ideal for high-volume production runs.

- Minimal Heat Affected Zone (HAZ): The focused laser beam of a fiber laser minimizes heat generation around the marking area, preventing warping or damage to the surrounding metal.

- Versatility: Fiber lasers can be used for various metal marking applications, including engraving, annealing, ablation, and drilling.

MOPA Technology: A Step Ahead in Metal Marking and Engraving

The Monport metal engraver GA utilizes a MOPA (Master Oscillator Power Amplifier) fiber laser source. This technology offers several advantages over standard fiber lasers for metal marking and engraving:

- Improved Pulse Quality: MOPA technology delivers cleaner and more consistent laser pulses, resulting in finer details and sharper engravings on metal surfaces.

- Greater Power Control: MOPA lasers provide a wider range of pulse widths and peak power, allowing for precise control over the marking depth and detail on different metals.

- Enhanced Material Compatibility: The improved pulse quality and controllability of MOPA lasers make them suitable for marking a broader range of metals compared to standard fiber lasers.

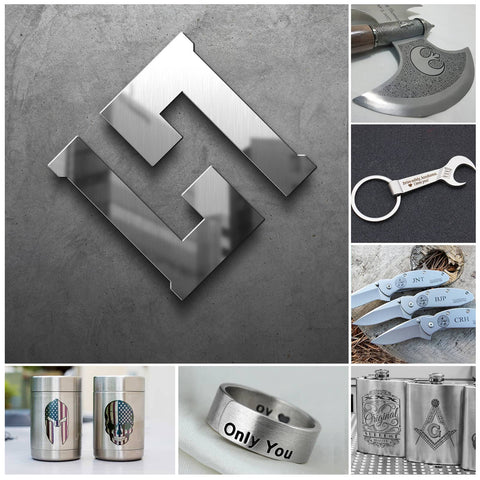

Introducing the Monport Metal Engraver GA: Unleash Your Metal Marking Creativity

The Monport metal engraver GA series is a powerful and user-friendly fiber laser marking machine designed to excel in metal marking and engraving applications. Here's a glimpse into its key features:

- Auto-Focus Technology: This innovative feature ensures high precision marking with a single click, eliminating the need for manual adjustments and improving workflow efficiency.

- Enhanced Performance: Rigorously tested components deliver exceptional stability, precision positioning, rapid marking speeds, and robust anti-interference capabilities.

- Widely Adjustable Frequency and Pulse Width: This allows for fine-tuning the laser output to achieve optimal results on various metals and for diverse applications.

- One-Minute Installation: The foldable vertical arm design simplifies setup, allowing even beginners to be up and running within minutes.

- Monport Laser Control Software Compatibility: Works seamlessly with popular software like LightBurn and EzCad2, offering a user-friendly interface for design and control.

Conclusion

OMTech CO2 lasers are excellent tools for working with various non-metallic materials. However, if your primary focus is metal marking and engraving, a fiber laser like the Monport GA is the clear choice. Its shorter wavelength, MOPA technology, and user-friendly features make it a powerful and versatile solution for creating permanent, high-quality marks on a wide range of metals.

Considering the Monport Metal engraver GA series?

The Monport metal engraver GA's auto-focus functionality, exceptional performance, and ease of use make it ideal for both experienced laser users and beginners venturing into the world of metal marking. Visit the Monport website to learn more about this innovative machine and explore its potential to elevate your metal marking projects.

Additional Considerations

- Material Compatibility: While the Monport metal engraver GA excels with various metals, it's essential to check the machine's specifications for compatible materials and recommended settings.

- Fume Extraction: Laser engraving on metals can generate fumes. Ensure you have a proper fume extraction system in place for a safe and healthy work environment.

We hope this blog post has clarified the limitations of CO2 lasers for metal marking and introduced you to the capabilities of the Monport GA fiber laser engraver. If you have any further questions about metal marking or the Monport metal engraver GA, feel free to leave a comment below.