Canva as a laser engraver might sound unconventional, but understanding the capabilities of green anodized aluminum and limitations of design tools is crucial for achieving the best results. When it comes to green anodized aluminum, its striking appearance and durability make it a popular choice for various applications. This material's unique color profile offers an excellent canvas for laser engraving, enabling the creation of high-contrast, long-lasting logos and designs.

In this blog post, we'll delve into the world of green anodized aluminum and explore how engraving logos on metal can enhance its aesthetic appeal. We'll also discuss the practicalities of using design tools and techniques to maximize the potential of this vibrant material.

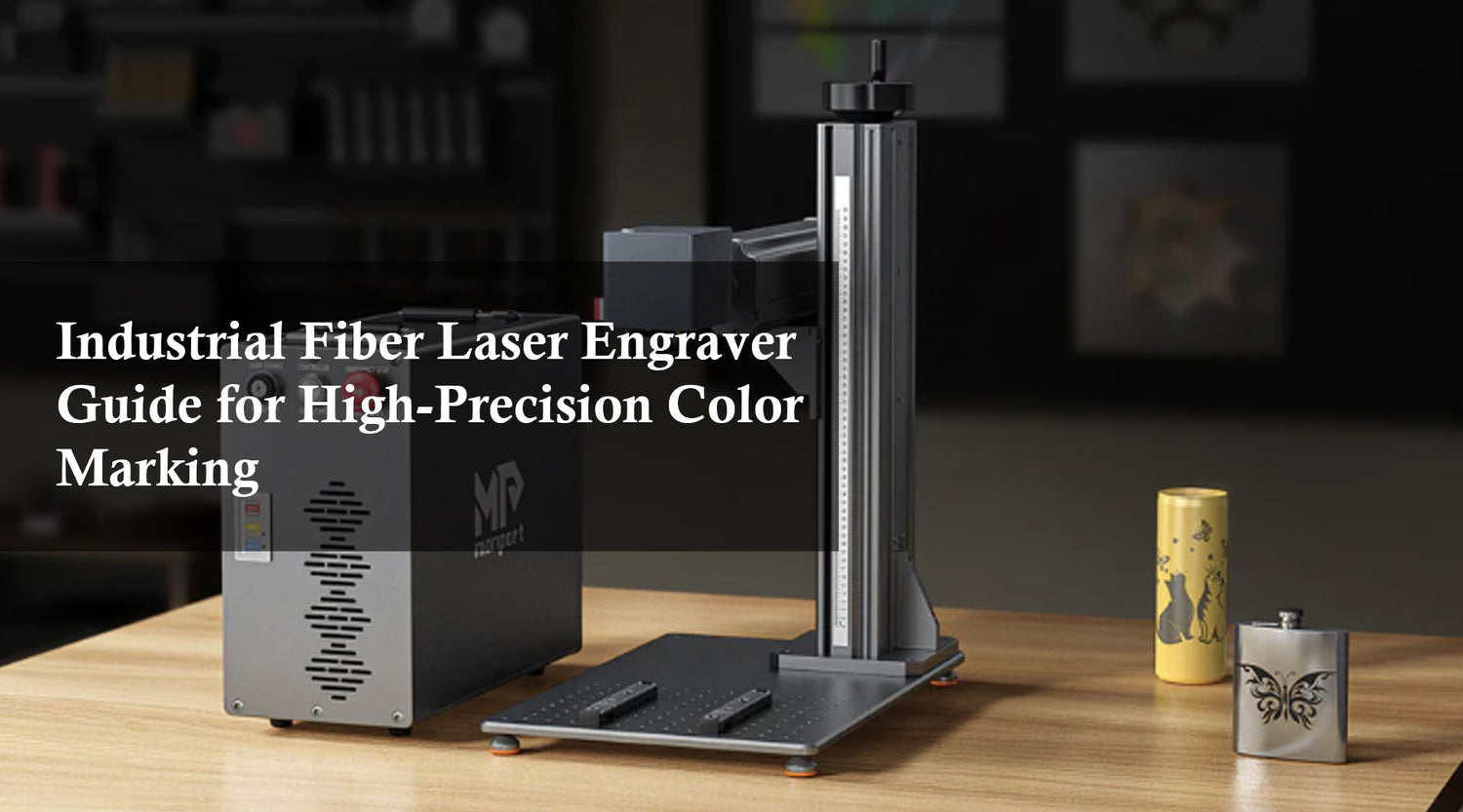

Monport GI 60W Integrated MOPA Fiber Laser Engraver & Marking Machine with Electric Lifting

The Beauty of Green Anodized Aluminum

Anodizing is a process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. Green anodized aluminum, in particular, offers a distinctive and contemporary look that complements a wide range of design styles. The color is achieved by incorporating dyes into the anodizing process, resulting in a vibrant and even finish.

Laser Engraving Logo on Metal: A Perfect Match

Laser engraving is a precise and efficient method for creating permanent markings on metal surfaces. When applied to green anodized aluminum, it produces high-contrast, detailed, and long-lasting engravings. The laser removes the anodized layer, revealing the underlying metal, which creates a striking visual contrast against the green background.

Engraving a logo on metal, such as green anodized aluminum, offers several advantages:

- Professionalism: A laser-engraved logo conveys a sense of quality and professionalism.

- Durability: The engraving is resistant to wear and tear, ensuring the logo remains clear and legible over time.

- Customization: You can customize the size, placement, and depth of the engraving to match your brand identity.

- Versatility: Laser engraving can be applied to various metal surfaces, not just green anodized aluminum.

Laser Engraving on Green Anodized Aluminum

Laser engraving is a precise and efficient method for creating permanent markings on metal surfaces. When applied to green anodized aluminum, it produces high-contrast, detailed, and long-lasting engravings. The laser removes the anodized layer, revealing the underlying metal, which creates a striking visual contrast against the green background.

The Benefits of Laser Engraving on Green Anodized Aluminum

- Durability: Laser-engraved markings are highly resistant to wear, scratches, and fading, ensuring the longevity of your product.

- Precision: Laser engraving offers exceptional precision, allowing for intricate designs and fine details.

- Versatility: You can engrave a wide range of designs, from simple logos to complex artwork.

- Speed: Laser engraving is a fast and efficient process, making it ideal for both small and large-scale projects.

- Customization: Create unique and personalized products with laser-engraved logos and designs.

Monport GI60 Fiber Laser: Your Partner in Metal Engraving

To achieve the best possible results when engraving on green anodized aluminum, you need a reliable and powerful laser engraver. The Monport GI60 Fiber Laser is an excellent choice for this task. Its advanced features and precision make it ideal for creating stunning engravings.

Key features of the Monport GI60 Fiber Laser include:

- Full Color Marking: While primarily focused on engraving, the GI60 can also produce color markings on certain metals, expanding your creative possibilities.

- Integrated Innovative Design: The compact and user-friendly design makes it easy to operate.

- Electric Lifting Focus: Ensures accurate focus for consistent engraving results.

- LightBurn Compatibility: Offers seamless integration with popular design software.

- Industry-Leading Heat Dissipation: Maintains optimal performance during extended use.

Machine Guide: Laser Parameters for Engraving Logo on Metal

Achieving optimal results when engraving on green anodized aluminum requires careful consideration of laser parameters. Here are some general guidelines:

- Power: Start with a lower power setting to avoid damaging the material. Gradually increase power as needed to achieve the desired engraving depth.

- Speed: A slower speed often produces better results, allowing for more precise control over the engraving process.

- Frequency: Adjust the laser frequency to optimize the engraving quality and appearance.

- Focus: Ensure the laser beam is focused correctly on the surface of the aluminum for consistent results.

Step-by-Step Guide to Laser Engraving on Logo on Metal

- Prepare your design: Create a vector-based design in your preferred design software.

- Clean the aluminum: Remove any dirt, grease, or contaminants from the surface.

- Set up the laser machine: Adjust the laser parameters based on the thickness of the aluminum and the desired engraving depth.

- Secure the material: Place the aluminum workpiece securely on the machine's worktable.

- Start the engraving process: Initiate the laser engraving process and monitor the machine's operation.

- Inspect the results: Once the engraving is complete, carefully inspect the workpiece for any imperfections.

Effortless Laser Marking with Monport Black Laser Marking Spray

Looking to elevate your laser engraving projects? Monport Black Laser Marking Spray is the solution you’ve been waiting for. This high-performance aerosol spray is designed for use with CO2 laser engraving machines, ensuring easy and precise results with every application. Whether you're personalizing jewelry, customizing glassware, or serializing tools, this spray provides you with high-contrast, permanent marks that stand out.

The Benefits of Using Black Laser Marking Spray

-

Compatible with CO2 Laser Engraving Machines Designed for use with CO2 laser engraving machines of 25 watts and above, Monport Black Laser Marking Spray is the ideal companion for your engraving needs. It transforms your metal surfaces into highly legible, permanent black marks after laser engraving, making it perfect for a wide range of applications from metalwork to custom art pieces.

-

Permanent, High-Contrast Marks When you apply Monport Black Laser Marking Spray, the result is a high-contrast, dark black mark on your metal surface that is permanent and durable. This spray works on various metals, including aluminum, stainless steel, and brass. The fine-grained formula ensures deep penetration into the metal, producing heat-resistant markings that will last for years, even under challenging conditions.

-

Even and Powerful Application With the advanced spray technology in Monport Black Laser Marking Spray, you can achieve a smooth, even application every time. The 14 oz can features an anti-clog nozzle that guarantees no blockages, making the spray process both easy and efficient. The nanoparticle formula delivers more coverage with a thinner coating, which results in a professional-quality finish for all your metal marking projects.

-

Easy to Use and Quick Drying Using Monport Black Laser Marking Spray couldn’t be simpler. Just shake the can for 2 minutes, spray from a distance of 6 to 8 inches, and let the surface dry for 5 minutes. Once it’s dry, you’re ready to engrave, saving you valuable time. After engraving, rinse and wipe away the residue to reveal your crisp, dark black markings without any fuss.

-

Effortless Cleanup and Maintenance After marking your metal pieces, simply rinse and wipe the surface to reveal your high-contrast engraving. The black laser marking spray ensures there is no residue left behind, so your workpieces remain clean and ready for immediate use. The easy cleanup means that you can maintain a smooth and efficient workflow, whether you’re working on a small DIY project or a larger-scale production.

Why Choose Monport Black Laser Marking Spray?

Monport’s Black Laser Marking Spray is a game-changer for anyone looking to create durable, precise, and high-quality laser marks on metal surfaces. Its compatibility with CO2 lasers, combined with its easy application and cleanup, makes it an indispensable tool for professionals and hobbyists alike. With Monport Black Laser Marking Spray, you can be confident that your metal engraving projects will have permanent, high-contrast results every time.

Add this versatile spray to your toolkit today and experience effortless laser marking like never before!

Conclusion

Green anodized aluminum combined with laser engraving creates a powerful and visually appealing combination. The durability, precision, and versatility of this pairing make it an excellent choice for a wide range of applications. With the right equipment, such as the Monport GI60 Fiber Laser, you can unlock the full potential of this material and create stunning products that stand out from the competition.