In modern industrial settings, maintaining optimal environmental conditions is crucial for both equipment performance and worker safety. Two essential components that help achieve this are industrial water chillers and industrial air purifiers. This guide will explore the importance of these systems, their functions, and how they can enhance industrial operations, including a detailed look at starting laser engraving using the Monport 80W CO2 laser engraver with a built-in chiller.

Introduction to Industrial Water Chillers

Industrial water chillers and industrial air purifiers play a significant role in various industries, ensuring machinery operates efficiently and maintaining air quality for a safe working environment. An industrial water chiller is essential for cooling equipment, while industrial air purifiers remove contaminants from the air, creating a healthier workplace. Understanding the benefits and applications of these systems can help businesses improve productivity and safety.

The Importance of Industrial Water Chillers

What is an Industrial Water Chiller?

An industrial water chiller is a system designed to remove heat from a process or equipment. It uses a refrigeration cycle to cool water, which is then circulated through heat exchangers to remove heat from machinery or processes. This cooling process is vital for maintaining optimal temperatures and preventing overheating.

Benefits of Using Industrial Water Chillers

- Enhanced Equipment Performance: By maintaining a consistent temperature, industrial water chillers prevent overheating and ensure machinery operates at peak efficiency.

- Increased Longevity: Regular cooling helps extend the lifespan of equipment by reducing wear and tear caused by excessive heat.

- Energy Efficiency: Modern water chillers are designed to be energy-efficient, reducing overall operational costs.

- Versatility: Industrial water chillers can be used in various applications, including plastic manufacturing, laser engraving, and food processing.

Starting Laser Engraving with the Monport 80W CO2 Laser Engraver with Built-In Chiller

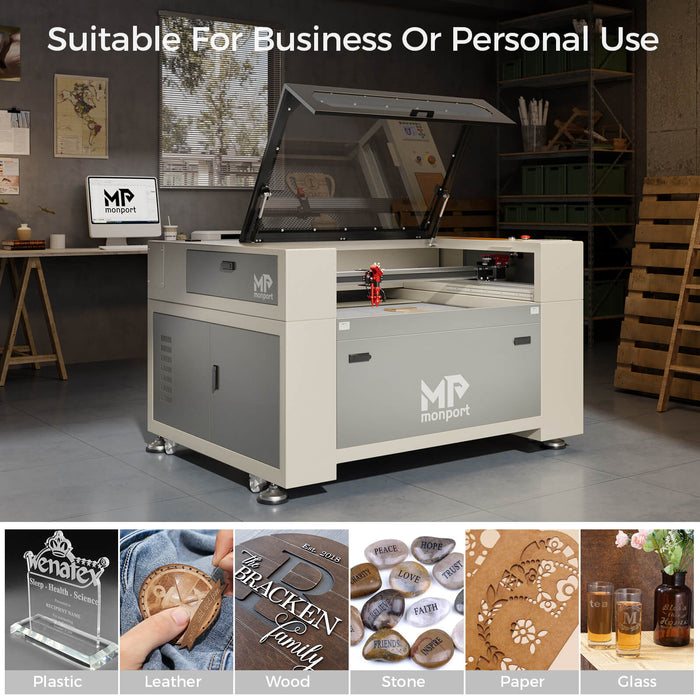

Monport 80W Built-in Chiller CO2 Laser Engraver & Cutter (36" x 24")

For businesses looking to start laser engraving, the Monport 80W CO2 laser engraver with a built-in chiller is an excellent choice. This integrated system ensures the laser operates at optimal temperatures, enhancing performance and longevity.

- Unboxing and Setup: Carefully unbox the Monport 80W CO2 laser engraver and ensure all components are present, including the built-in chiller.

- Assembly: Follow the user manual to assemble the laser engraver and connect the built-in chiller.

- Software Installation: Install the included software to design and control your engraving projects.

- Calibration: Calibrate the laser and chiller to ensure they function correctly and efficiently.

- Testing: Perform a test engraving to familiarize yourself with the machine and make any necessary adjustments.

The Role of Industrial Air Purifiers

What is an Industrial Air Purifier?

Industrial air purifiers are systems designed to remove pollutants, particles, and contaminants from the air in industrial settings. These purifiers use various technologies, such as HEPA filters, activated carbon, and UV light, to clean the air and improve indoor air quality.

Benefits of Using Industrial Air Purifiers

- Improved Air Quality: Industrial air purifiers effectively remove harmful particles, dust, and fumes, creating a healthier work environment.

- Enhanced Worker Safety: Cleaner air reduces the risk of respiratory issues and other health problems among workers.

- Compliance with Regulations: Many industries are required to maintain specific air quality standards. Industrial air purifiers help meet these regulations.

- Reduced Maintenance Costs: By removing contaminants, air purifiers help protect machinery and equipment from dust and debris, reducing maintenance needs.

Applications of Industrial Air Purifiers

Industrial air purifiers are used in various settings, including:

- Manufacturing Plants: To remove dust and fumes generated during production processes.

- Warehouses: To maintain clean air and protect stored goods.

- Laboratories: To ensure a contaminant-free environment for sensitive experiments.

- Offices: To improve indoor air quality for administrative staff.

How Industrial Water Chillers and Air Purifiers Enhance Industrial Operations

Synergy Between Cooling and Air Purification

Using industrial water chillers and air purifiers together creates a synergistic effect that enhances overall operational efficiency:

- Consistent Temperature Control: Water chillers maintain optimal temperatures, preventing equipment from overheating.

- Clean Air Environment: Air purifiers remove contaminants, ensuring machinery operates in a clean environment, reducing wear and tear.

- Enhanced Productivity: A stable temperature and clean air lead to fewer interruptions and downtime, boosting productivity.

- Worker Safety and Comfort: Clean air and controlled temperatures create a safer and more comfortable workplace, reducing absenteeism and increasing morale.

Specific Use Case: Laser Engraving

Laser engraving is a precise and intricate process that benefits significantly from using both water chillers and air purifiers:

- Temperature Control: The Monport 80W CO2 laser engraver with a built-in chiller ensures the laser operates within safe temperature ranges, preventing overheating and ensuring consistent performance.

- Air Quality Management: Using an industrial air purifier in the laser engraving workspace removes fumes and particles generated during the engraving process, protecting both the equipment and operators.

Key Takeaways

- Industrial Water Chillers: Essential for cooling machinery and processes, enhancing performance, and extending equipment lifespan.

- Industrial Air Purifiers: Crucial for removing contaminants from the air, improving air quality, and ensuring worker safety.

- Synergistic Benefits: Using both systems together optimizes operational efficiency, productivity, and safety.

- Laser Engraving Application: The Monport 80W CO2 laser engraver with a built-in chiller exemplifies the importance of temperature control and air quality in precision tasks like laser engraving.

Conclusion

Industrial water chillers and industrial air purifiers are indispensable in maintaining optimal working conditions in various industrial settings. They enhance equipment performance, ensure worker safety, and improve overall operational efficiency. For businesses interested in laser engraving, the Monport 80W CO2 laser engraver with a built-in chiller offers an excellent starting point, combining effective cooling with precision engraving capabilities. By investing in these essential systems, businesses can achieve higher productivity, better compliance with regulations, and a healthier work environment.