The ability to permanently mark metal with laser engraving steel plates has long been a valued skill, used for everything from creating decorative art to identifying tools like the best metal laser engraver for sale. Today, laser engraving projects offers a precise and versatile way in engraving letters on metal, logos, and designs onto metal surfaces. This guide delves into the process of metal letter engraving, exploring the steps involved on how to engrave letters on metal, essential considerations, and the advantages of using a Monport GQ 30W Fiber Laser Machine.

Monport GQ 30W (5.9" x 5.9") Fiber Laser Engraver & Marking Machine with FDA Approval

Use code BESTMP10 at checkout – click here to shop!

Understanding Laser Engraving Steel Plates

Laser engraving uses a focused light beam to remove metal material precisely, creating permanent marks or patterns.

When engraving steel, the laser melts or vaporizes the surface, leaving a detailed indentation or contrasting color.

With the Monport GQ 30W, you can achieve high precision and durability, making it perfect for metal letter engraving, serial number marking, and custom logos.

The Benefits of Laser Engraving Steel Plates

-

-

Versatility: Works effectively on stainless steel, mild steel, and tool steel.

-

Speed & Efficiency: The Monport GQ 30W completes engraving projects quickly with minimal setup.

-

Clean Operation: No ink, no chemicals, no debris — just pure precision.

Step-by-step Guide for Laser Engraving Steel Plates

1. Prepare Your Design: Choose your desired design for engraving. You can create your own design using graphic design software or download pre-made designs from online resources.

2. Prepare the Steel Plate: Ensure the steel plate is clean, free of dirt, oil, or any contaminants that could affect the engraving process. You may need to use a degreaser or abrasive cleaner to prepare the surface before metal letter engraving.

3. Import Design and Set Laser Parameters: Import your chosen design into the laser engraving software provided with your machine (e.g., LightBurn). Set appropriate laser parameters like power, speed, and frequency based on the thickness of the steel plate and your desired engraving depth. The Monport GQ 30W features user-friendly software that simplifies this process.

4. Secure the Steel Plate: Secure the steel plate firmly onto the laser engraving machine's workbed using clamps or magnets. The Monport GQ metal laser engraver for sale 30W's built-in workspace grid and removable positioning bars ensure precise placement.

5. Laser Engraving Process: Once everything is set up, initiate the laser engraving process. The laser beam will follow the design path, etching your chosen design onto the steel plate. The Monport GQ 30W's Galvo-tech Control ensures high-speed engraving with exceptional accuracy.

6. Cleaning and Finishing: After the engraving is complete, gently clean the steel plate to remove any dust or debris. You can also apply a light coat of oil to protect the engraved area from corrosion. This final touch is important when engraving letters on metal that will be exposed to outdoor elements.

How to Engrave Letters on Metal: Tips & Tricks for Flawless Metal Engravings

Now that you've explored the process and the advantages of laser engraving steel plates, let's delve into some helpful tips and tricks to ensure your lettering laser engraving projects are crisp, clear, and professional-looking. Whether you're metal letter engraving for signage, art, or tools, these tips will help using a metal laser engraver for sale:

Choosing the Right Font:

- Simplicity is Key: For beginners, opt for fonts with clean lines and minimal details. Avoid fonts with very thin lines or intricate serifs, as these can become lost during the engraving process.

-

Test and Adjust: If you're unsure how a specific font will translate to engraving, test it on a scrap piece of metal before engraving your final design. This allows you to fine-tune the font size and adjust for any potential issues with engraving letters on metal.

Optimizing Laser Parameters for Lettering:

- Power and Speed: Generally, for clear and defined lettering on steel plates, you'll want to use a higher laser power setting combined with a slower engraving speed. This ensures the laser beam melts the metal sufficiently to create a visible mark without burning or warping the steel. Consult your machine's manual or software for specific recommendations based on your steel plate thickness and desired engraving depth.

- Test Runs and Adjustments: Don't hesitate to perform test engravings with different power and speed settings to achieve the optimal results for your desired lettering depth and crispness.

Ensuring Precise Lettering Placement:

- Software Alignment: Utilize the alignment tools within your laser engraving software to precisely position your lettering on the steel plate. The Monport GQ 30W's user-friendly software makes this process straightforward.

- Physical Guides (Optional): For added precision, consider using physical guides like masking tape or stencils to mark the desired lettering placement on the steel plate before engraving.

Additional Tips for a Flawless Finish:

- Cleanliness is Crucial: Always ensure the steel plate is clean and free of dirt, oil, or any contaminants before engraving. This prevents imperfections and allows for a clean laser beam interaction with the metal surface.

- Fume Extraction: Laser engraving steel does generate some fumes. Ensure proper ventilation is in place to remove these fumes and maintain a safe working environment. Most laser machines, including the Monport GQ 30W, come equipped with exhaust ports for this purpose.

- Post-Engraving Cleaning: After engraving, gently clean the steel plate to remove any dust or debris left behind. You can also use a light coat of oil to protect the engraved area, especially if the steel plate will be exposed to the elements.

With these tips and tricks in mind, you're well on your way to mastering the art of how to engrave letters on metal. The Monport GQ 30W Fiber Laser Machine, with its user-friendly features and precise engraving capabilities, is the perfect tool to transform your lettering laser engraving projects into stunning creations!

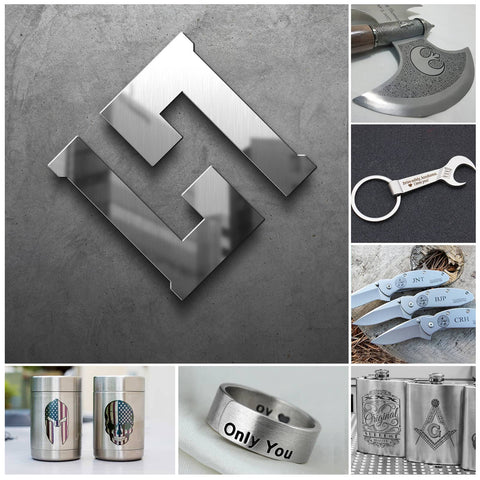

Unlocking Creative Potential: Applications for Laser-Engraved Steel Plates

Laser engraving opens doors to a wide range of creative applications for steel plates:

- Personalized Metal Signage: Create custom signage for homes, businesses, or even as unique nameplates.

- Engraved Tools and Equipment: Personalize tools and equipment with names, logos, or serial numbers for easy identification and ownership tracking.

- Commemorative Gifts and Awards: Engrave special messages, dates, or logos onto steel plates to create unique and personalized gifts or awards for any occasion.

- Art and Design: The precise engraving capabilities of laser technology make it ideal for creating artistic designs, patterns, or even incorporating steel plates into mixed-media artwork.

- Industrial Applications: Laser engraving steel plates finds applications in various industrial settings, such as marking serial numbers, part identification codes, or logos on manufactured components.

- Jewelry Making: While not ideal for all jewelry applications due to steel's hardness, laser engraving can be used to create unique markings or textures on certain types of steel jewelry pieces.

Investing in a Monport GQ 30W Fiber Laser Machine

The Monport GQ 30W Fiber Laser Machine empowers you to explore the world of laser engraving steel plates and unlock its creative potential of how to metal letter engraving. This versatile machine offers a blend of:

- Precision and Performance: The Galvo-tech Control and Raycus Fiber Laser Source ensure exceptional results with detailed engravings and compatibility with a wide range of metals.

- User-Friendly Features: The intuitive software, workspace design, and additional laser guidance features make it easy to learn and operate, even for beginners.

- Versatility: Beyond steel plates, the Monport GQ 30W can engrave on various metal materials like steel, aluminum, brass, silver and gold, expanding your creative possibilities.

- Durability and Reliability: Built with high-quality components, the Monport GQ 30W offers a long lifespan and reliable performance for all your laser engraving projects.

FAQs: How to Engrave Metal with Letters

How to laser engrave metal at home?

With a fiber laser system, proper ventilation, and safety practices, home engraving is achievable.

What metals can be engraved?

Steel, aluminum, brass, and other common metals can be engraved.

Is laser engraving better than hand engraving?

Laser engraving offers greater consistency and speed than manual methods.

Can small letters be engraved clearly?

Yes, laser systems excel at fine metal letter engraving.

Does engraving weaken the metal?

Surface engraving does not affect the metal’s structural strength

Conclusion

Understanding how to laser engrave metal opens up endless possibilities for precise and lasting designs. Whether you are engraving letters on metal for signage, tools, or creative projects, laser engraving provides control, durability, and professional results. With the right approach, engraving letters into metal becomes a reliable and repeatable process.

Taking the First Step: Explore the World of Laser Engraving

Laser engraving steel plates has never been more accessible or precise. With the Monport GQ 30W Fiber Laser Engraver, you can bring your creative and industrial projects to life with unmatched accuracy.

Whether you’re customizing tools, crafting signage, or designing gifts — the Monport GQ 30W is your go-to solution for professional-grade results.

🎯 Use code BESTMP10 at checkout – click here to shop now!