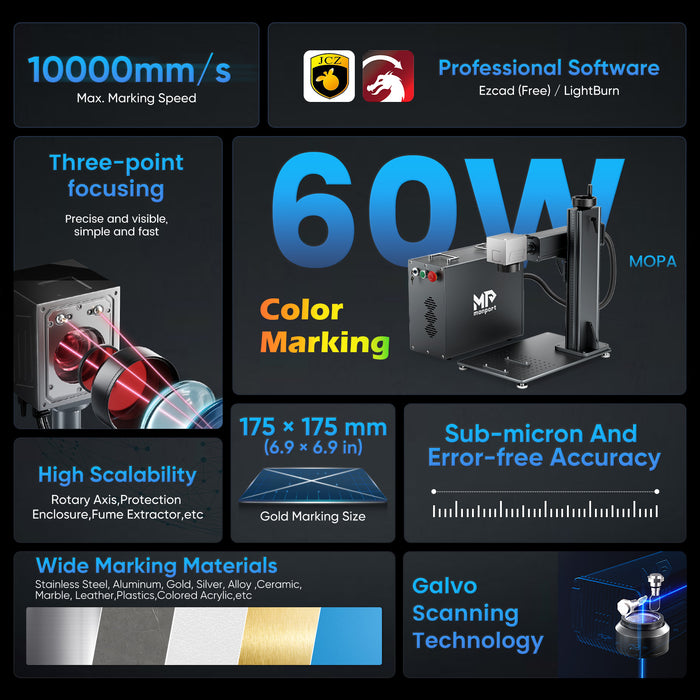

Welcome to our Buying Guide, where we unravel the intricacies of fiber lasers and delve into the cutting-edge technology behind Monport's 60w Split MOPA Fiber Laser Engraver & Marking Machine with Manual Focus. If you've ever wondered, What is a fiber laser used for? or sought to understand the fundamental working principles of these remarkable devices, you're in the right place. The rotary laser is a pivotal tool for engraving cylindrical objects, such as mugs, bottles, and other round items. When combined with the precision and power of a Monport 60W Split MOPA Fiber Laser, it enables users to take their engraving projects to the next level. The MOPA (Master Oscillator Power Amplifier) configuration in the fiber laser provides superior control over the engraving process, delivering high-quality results on various materials, including metals, plastics, and more. This versatility makes the Monport 60W Split MOPA Fiber Laser an excellent choice for both intricate designs and large-volume production needs.

Key features such as the rotary attachment for cylindrical objects allow for a seamless engraving experience, further enhancing its capability for professional and commercial applications. Whether you’re marking metals or engraving detailed artwork, this fiber laser offers precision and speed, making it an ideal solution for businesses looking to provide customized, durable products.

Monport 60w Split MOPA Fiber Laser Engraver & Marking Machine With Manual Focus

What is a Fiber Laser Used for?

Fiber lasers are versatile tools that are widely used for various applications across industries. Some common uses of fiber lasers include:

- Metal Marking: Fiber lasers are ideal for marking a wide range of metals, including stainless steel, aluminum, brass, and more. From serial numbers to barcodes, fiber lasers provide high-quality and permanent markings on metal surfaces.

- Metal Engraving: With their precise and fine-tuned laser beams, fiber lasers are used for engraving intricate designs, logos, and text on metal surfaces. This makes them an essential tool for customizing metal products and components.

- Cutting: Fiber lasers are also utilized for cutting metal sheets and components with high precision and speed. They offer a clean and efficient cutting process, making them suitable for various industries such as automotive, aerospace, and jewelry manufacturing.

- Welding: Fiber lasers can be used for welding metal components together with accuracy and control. Their ability to produce strong and reliable welds makes them a preferred choice for joining metal parts in industrial applications.

Fiber Laser Working Principle

Fiber lasers operate based on the principle of stimulated emission of radiation. The working principle of a fiber laser can be summarized as follows:

- Pump Source: A pump source, typically a semiconductor diode, generates a high-power laser beam that is then delivered to the fiber optic cable.

- Fiber Optic Cable: The laser beam is transmitted through the fiber optic cable, which is doped with rare-earth elements such as ytterbium, neodymium, or erbium. These dopants enhance the laser efficiency and power output.

- Laser Cavity: Within the fiber laser cavity, the laser beam is amplified as it interacts with the dopants in the fiber optic cable through a process called stimulated emission. This amplification results in a coherent and high-energy laser beam.

- Output Coupler: The amplified laser beam exits the fiber laser cavity through an output coupler, which directs the laser beam towards the workpiece for engraving, marking, cutting, or welding.

FAQs

- What materials can be processed using a fiber laser engraver?

- Fiber lasers can process a wide range of materials, including metals, plastics, ceramics, and some organic materials.

- Is the Monport 60w Split MOPA Fiber Laser Engraver easy to operate?

- Yes, the Monport fiber laser engraver is designed for user-friendly operation, featuring manual focus controls for precise engraving and marking.

Important Details

The Monport 60w Split MOPA Fiber Laser Engraver & Marking Machine is a powerful and efficient tool for various marking and engraving applications. Some key details of this product include:

- Power Output: 60W

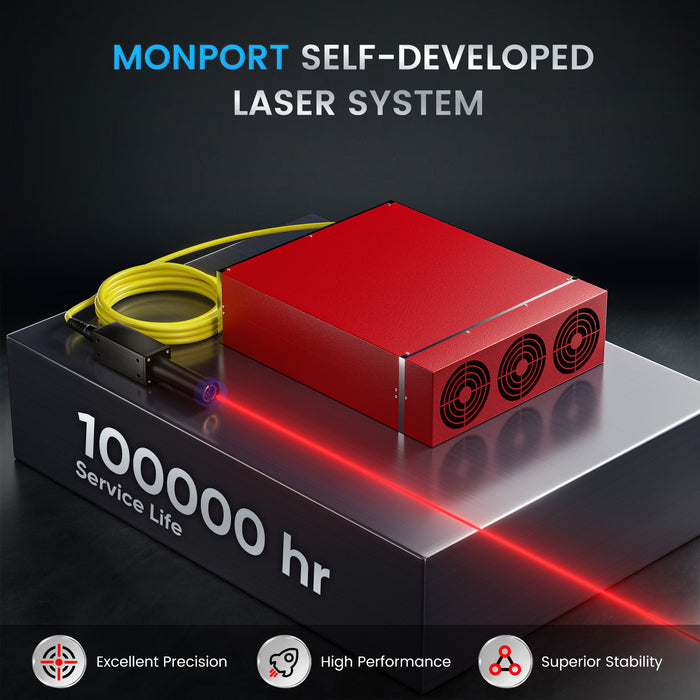

- Laser Source: MOPA Fiber Laser

- Split Design: Allows for easy maintenance and servicing

- Manual Focus: Enables precise control over the engraving process

- Compatibility: Suitable for marking and engraving on a variety of materials

Takeaways

When considering the purchase of a fiber laser engraver, it is essential to understand its working principle and potential applications. The Monport 60w Split MOPA Fiber Laser Engraver offers a reliable solution for high-quality marking and engraving tasks, thanks to its advanced features and user-friendly design.

Conclusion

In conclusion, fiber lasers have become indispensable tools in modern manufacturing, offering unmatched versatility and precision for a wide array of applications, from marking and engraving to cutting and welding. Understanding the inner workings of fiber lasers and their numerous benefits is crucial for anyone looking to invest in high-quality laser engravers.

The Monport 60W Split MOPA Fiber Laser Engraver & Marking Machine with Manual Focus stands out as a top-tier option for professionals and businesses seeking both precision and efficiency in their engraving and marking tasks. Its MOPA technology ensures superior control over the laser pulse, delivering high-quality, detailed results on a variety of materials, including metals, plastics, and ceramics. With its robust features and exceptional performance, this fiber laser is a reliable choice for achieving professional-grade results, making it an excellent investment for those looking to enhance their laser engraving capabilities.