Ⅰ. Crystal-All you need to know

What is a Crystal?

A crystal is made up of materials that have been arranged in a particular order by atoms, molecules, or ions. The lattice that develops is three-dimensional. Crystals have distinct structures because of the repeating components. Flat sections or faces, as well as well-defined angles, can be seen in large crystals. Euhedral crystals have well-defined flat faces, whereas anhedral crystals lack distinct faces. Quasicrystals are crystals made up of organized arrays of atoms that aren't always periodic. The term "crystal" is derived from the Ancient Greek word krustallos, which means "rock crystal" as well as "ice."

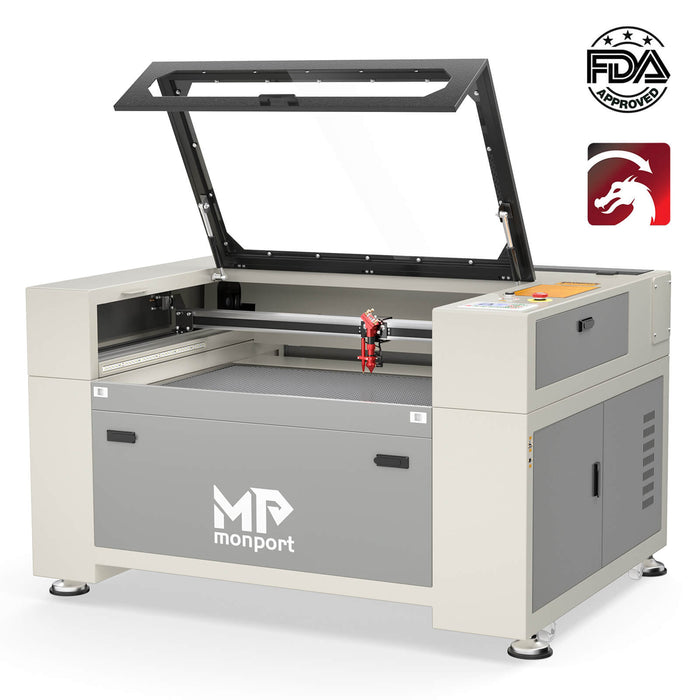

Crystal gift laser engraving and engraving machine adopts high-performance laser and numerical control technology, mainly composed of optical system, control system and computer software. The energy density of the crystal gift laser engraving and engraving machine must be greater than a certain critical value, or threshold value, which can damage the glass. The high concentration of the laser beam in space and time can reduce the spot diameter to the micron level to obtain a high power density. The smaller the spot, the greater the energy density. Through proper focusing, the energy density of the laser can be made. The laser generates pulses in a very short time. Its energy can instantly heat and break the crystal gift, thereby generating extremely small white spots. Not only can the predetermined shape be carved in the glass, but also the rest of the crystal gift remains intact. Industrial laser engravers are essential in this process, offering the precision needed for detailed engraving. Crystal is a crystalline form of silica, while glass is just a molten mixture containing silica. The unit price of crystal is several times or even dozens of times higher than that of glass.

How are Crystals formed?

Crystals may be created in a variety of methods. When pressurized molten carbon cools fast, certain crystalline crystals form. Diamonds are produced in this manner. When a solution's liquid evaporates, other crystals develop. This is how amethyst, a purple quartz crystal, is made. Amethyst is made up of a highly concentrated silicon dioxide (SiO2) solution with traces of iron. This solution becomes trapped within a lava bubble. The silicon and oxygen ions gently organize themselves to form a crystal when the water evaporates. The purple color of amethyst is due to the presence of iron. Crystals, on the other hand, cannot form in the center of a liquid. Therefore, they require a beginning place to develop. Once a nucleus is formed, the crystal can begin to expand. A seed crystal is another name for a nucleus, and nucleation is the name for this process. Amethyst crystals grow on the interior of lava bubbles in the case of amethyst. As the lava bubbles cool, stones with crystals on the interior develop. A geode is a name given to such a structure like this.

Ⅱ. Laser etching & engraving crystal

How to use laser machine engraver a Crystal

The term "laser cut" refers to stones that have been cut in a unique form by skilled gem cutters. In truth, there was no laser-cutting machine that could cut stones completely until more recently. Lasers are used in gem-cutting factories to give raw diamonds a preforming rough shape, making the gem cutter's job easier. However, most natural stones are still carved by hand to some extent or another. This will not continue long, as technological advancements will allow gem-cutting techniques to be automated in a short period, and that is where the Monport industrial laser engraver comes into play.

Design the pattern on software

Cutting a crystal is relatively straightforward; you start by pressing commands into a computer to specify the regions you need cut and reshaped. Then, the computer will accurately follow the instructions that you give it.

Using a laser machine to etching out the sign

Once you are done typing in the required dimensions, the industrial laser engraver will do the rest. The laser beam will cut the lattice at the exact position you commanded the computer to cut. This makes for a more stress-free and contactless process before handing it over to a gem cutter.

Ⅲ.Applications

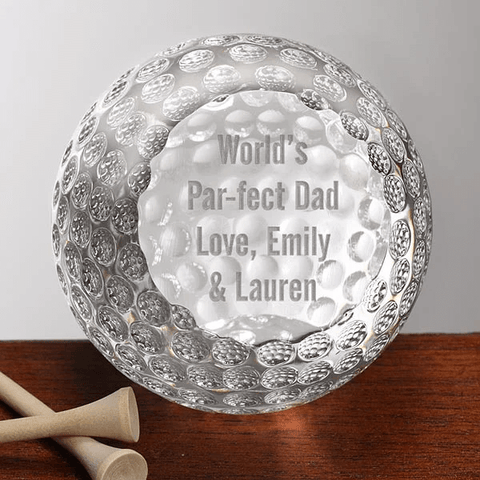

Maybe you are interested in selling trophies to sports teams, or selling high-end awards to the corporate market, or maybe selling Engravable gifts to the public. Regardless of your business direction, have you considered selling crystal products? One of the great advantages of the similarity between crystal goods and glass goods is that it can be skillfully integrated into any other similar glass materials used to make prizes and gifts: glass, crystal and optical crystal. Or all these market channels may even become one of your best-selling product lines. According to most people, crystal products are still popular in the field of awards and gifts in the industry. The flash, gloss and smoothness of these products make them high-end attractive and attractive to customers with large budgets (such as those in the enterprise market). Industry suppliers provide a variety of glass and crystal products, from trophies and plaques to vases, photo frames and office desk accessories. Innovation makes crystal carving produce qualitative changes. You can do a lot of things with crystal and glass. Crystal awards and gifts have incomparable attraction to other products. Compared with low-end glass, crystal is more elegant and shiny than glass, especially after personalization. Crystal will certainly attract many markets. If you want to increase your products and income, you should consider adding it to your business.

If you are going to sell crystal gifts and prizes, you need a way to personalize these products. The three methods currently used in this industry are sand carving, laser engraving, and mechanical carving. As more and more shop owners buy industrial laser engravers, more and more people begin to study etching glass. CO2 lasers are an excellent choice for engraving glass. Laser engraving is highly praised for its simplicity. Laser engraving machine is widely used in two-dimensional crystal photo engraving, personalized crystal inner carving gift customization, and high-precision reading crystal products batch processing.

Because this is a non-contact process, the only thing that contacts the crystal is a beam of light, so you don't have to worry about clamping or water cooling the crystal as you do when rotating engraving or preparing photoresist masks or stencils. Since there is no need for fixing except for cylindrical objects, laser engraving provides faster setup and faster processing time than the other two methods. Moreover, everyone in the industry knows that time is money. If mass output is important to you, laser engraving is definitely an option.

Laser etching can be used to mark various glass and crystal gifts and prizes. For example, if you plan to laser engrave cylindrical objects, such as crystal balls, Monport will provide a rotation axis to help you solve this problem easily. Laser engraved glass looks very different from glass marked by other personalized methods. You can get high-quality carving results, but it does look different. You can't get any significant depth. In most cases, the CO2 laser works by evaporating the surface of the material being engraved. However, in the case of glass, the industrial laser engraver will smash or break the surface under the microscope, which may leave very tiny flakes or fragments, and may cause uneven appearance of the filled area. When this happens, sometimes very fine sandpaper can be used to grind it to make it smoother.