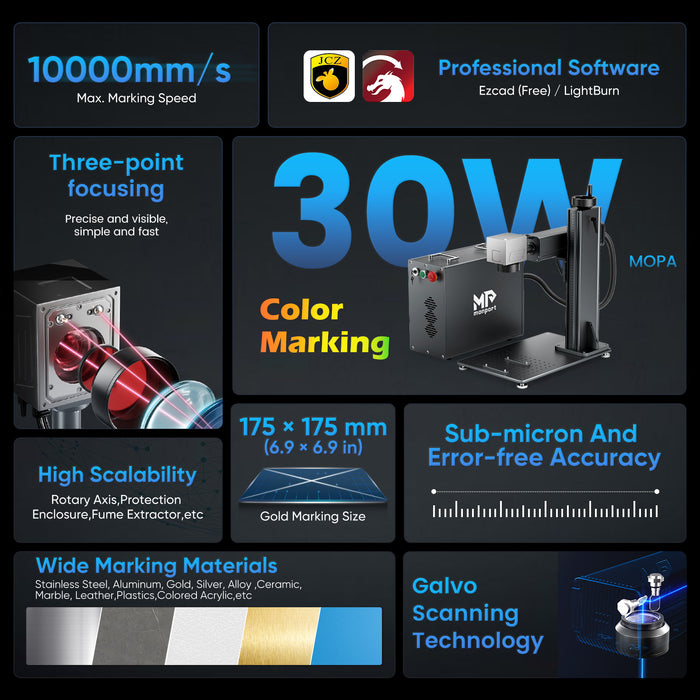

In the world of laser engraving, precision, and versatility are paramount. Enter the 30W MOPA fiber laser and the MOPA laser engraver or range laser, Two powerful tools that are revolutionizing the field by allowing for intricate, colorful engravings on a variety of materials, especially when used with black laser marking spray to enhance contrast and clarity. This article explores the process of color laser engraving, specifically focusing on how to achieve stunning results using a Monport 30W fiber laser engraver.

Whether you're marking intricate designs or experimenting with color engraving on metal, the Monport 30W fiber laser engraver delivers professional, eye-catching results every time. Ready to take your engraving to the next level? Use code BESTMP10 at checkout – click here to shop!

Understanding the 30W MOPA Fiber Laser

The 30W MOPA laser stands out due to its ability to manipulate pulse duration, a feature not available in standard fiber lasers. This flexibility in pulse control allows users to create a spectrum of colors on metal surfaces by adjusting the laser parameters, especially when paired with black laser marking spray for enhanced contrast and vibrant results.

The range laser (Master Oscillator Power Amplifier) technology enables the laser to produce different shades and tones by altering the heat input, which affects the oxidation levels on the metal surface.

Setting Up Your MOPA Laser Engraver

Before diving into the engraving process, it is crucial to set up your Monport 30W fiber laser engraver correctly. Begin by ensuring your work area is clean and that the engraver is placed on a stable surface. Proper ventilation is essential to avoid inhaling any fumes produced during engraving.

-

Software Configuration: Install and configure the necessary software that comes with your MOPA laser engraver. This software will allow you to input your design and adjust the engraving parameters.

-

Material Preparation: Select the material you wish to engrave on. Metals like stainless steel and titanium are excellent choices for color engraving with a 30W MOPA laser fiber laser due to their responsive surface properties.

-

Safety Measures: Always wear appropriate safety gear, including laser safety glasses, to protect your eyes from harmful laser radiation.

Engraving Process with the Monport 30W Fiber Laser Engraver

Step 1: Designing Your Artwork

Create or import your design into the laser engraving software. The software will translate your design into instructions that the MOPA laser engraver will follow. Pay attention to details such as line thickness and spacing, as these can affect the final color outcome, especially when using black laser marking spray to achieve sharp and vivid contrasts.

Step 2: Setting Parameters

The key to achieving vibrant colors with a 30W range laser lies in fine-tuning the laser parameters. Here are some critical settings to adjust:

- Pulse Duration: Shorter pulses generally produce lighter colors, while longer pulses can generate darker shades.

- Frequency: Higher frequencies can result in more vibrant colors.

- Power and Speed: Balancing these two settings is crucial. Too much power can burn the material, while too little might not produce the desired color.

Experiment with these settings on a test piece of the same material to find the perfect combination for your design.

Step 3: Engraving

Once you have your parameters set, position your material on the engraving bed. Double-check the alignment to ensure your design is centered. Start the engraving process and monitor it closely to make any necessary adjustments.

Step 4: Post-Engraving Finishing

After engraving, some materials may require additional finishing steps to enhance the color and durability of the engraving. This might include cleaning the surface with a mild solvent to remove any residue, especially when using black laser marking spray to ensure a clean and vibrant finish.

Unlock Flawless Metal Marking with Monport Black Laser Marking Spray

When it comes to creating professional-grade metal engravings, Monport black laser marking spray is a must-have for makers, hobbyists, and professionals alike. This powerful aerosol spray is specially formulated to work with CO2 laser machines of 25 watts and above, producing permanent black markings with exceptional contrast. Whether you're working on stainless steel, brass, or aluminum, the black laser marking spray bonds effortlessly to the surface, allowing for detailed and precise designs. Its fine-particle formula and anti-clog nozzle ensure smooth, even coverage every time. Drying in just five minutes, the black laser marking spray is easy to use and leaves no sticky residue after rinsing. From customizing jewelry to labeling tools or decorating metalware, the black laser marking spray from Monport delivers clean, bold results that last.

Key Takeaways

- Versatility of 30W MOPA Fiber Laser: The ability to adjust pulse duration and frequency makes the 30W range laser fiber laser ideal for creating a wide range of colors on metal surfaces.

- Importance of Parameter Adjustment: Fine-tuning the laser settings is crucial for achieving the desired colors and effects.

- Material Selection: Metals like stainless steel and titanium are preferred for color engraving due to their reactive surface properties.

- Safety First: Always prioritize safety by wearing appropriate gear and ensuring proper ventilation in your workspace.

FAQs: Color Engraving with a 30W MOPA Laser

1. Can the Monport 30W MOPA fiber laser engraver create full-color designs on metal?

Yes! The pulse modulation of the 30W MOPA allows for a wide range of colors through oxidation—perfect for decorative applications.

2. Is black laser marking spray necessary for all metal engraving?

While not mandatory, using black laser marking spray dramatically enhances contrast and legibility, especially for fine details.

3. What types of metal work best with color laser engraving?

Stainless steel, titanium, and anodized aluminum respond best, providing vibrant color changes when using the 30W MOPA laser engraver.

4. How long does the black laser marking spray take to dry?

Monport’s black laser spray dries in about 5 minutes and rinses cleanly without sticky residue.

5. Can I use the 30W MOPA fiber laser for engraving plastic or leather?

No, the MOPA fiber laser is optimized for metals. For organic materials, a CO2 laser engraver is more suitable.

Conclusion

The Monport 30W fiber laser engraver, powered by MOPA laser technology, opens up a new realm of possibilities in the field of laser engraving. By understanding and manipulating the various laser parameters, users can create stunning, colorful engravings that stand out in terms of both aesthetics and precision, especially when utilizing black laser marking spray. Whether you're a professional engraver or a hobbyist, mastering the use of a 30W MOPA laser fiber laser can significantly enhance the quality and diversity of your engraving projects.

In summary, the combination of a 30W MOPA laser fiber laser and a range laser engraver provides unparalleled control over the engraving process, enabling the creation of detailed, colorful designs that were previously unattainable with standard fiber lasers. With the right setup, materials, and safety measures, anyone can achieve professional-grade results and bring a spectrum of colors to their laser engraving endeavors.

Celebrate Business Week with Monport! Enjoy up to 30% OFF on our premium laser engraving machines and unlock incredible free gifts to elevate your projects. Buy a CO₂ laser and receive a FREE Water Chiller, Rotary Axis, and LightBurn software. Purchase a Fiber Laser and get a FREE Rotary Axis. Plus, score a special $130 OFF on bundle deals and 30% OFF laser engraving materials. Don’t wait — use code BESTMP10 at checkout and click here to shop now!