Introduction

Plywood sheets stand as a versatile material, finding its way into numerous applications across industries due to its durability, affordability, and ease of use. However, when it comes to laser cutting, not all plywood sheets are created equal. Understanding the intricacies of plywood sheet selection is crucial for achieving optimal results in laser cutting projects. In this guide, we'll navigate the maze of plywood sheet options, equipping you with the knowledge to pick the best plywood for your laser cutting endeavors.

Understanding Plywood Basics

Before delving into the selection process, it's essential to grasp the fundamentals of plywood sheets. Comprising multiple layers of wood veneers bonded together with adhesive, plywood sheets come in various grades, thicknesses, and compositions. Each plywood sheet type offers distinct characteristics that impact its suitability for laser cutting applications.

When selecting plywood for laser cutting, several factors come into play, including:

-

Plywood Grade: Plywood is available in different grades, ranging from A to D, with A being the highest quality and D being the lowest. Higher-grade plywood typically features fewer voids and imperfections, resulting in smoother cuts and cleaner edges during laser cutting.

-

Core Material: Plywood cores may consist of hardwood, softwood, or a combination of both. Hardwood cores offer greater stability and density, resulting in cleaner cuts and reduced charring during laser cutting.

-

Adhesive Type: The type of adhesive used to bond plywood layers can impact its laser cutting performance. Plywood with formaldehyde-free or low-emission adhesives is preferable, as it reduces the risk of toxic fumes and residue during laser cutting.

-

Surface Finish: The surface finish of plywood, such as smooth, textured, or veneered, can affect laser cutting results. Smooth, flat surfaces yield cleaner cuts and better engraving quality compared to textured or uneven surfaces.

-

Thickness: Plywood thickness directly influences laser cutting parameters such as speed, power, and focus depth. Thicker plywood requires higher laser power and slower cutting speeds to achieve clean cuts without charring or burning.

Choosing the Right Plywood for Laser Cutting

Based on the factors mentioned above, here are some recommendations for selecting plywood for laser cutting projects:

- Grade A or B plywood with hardwood cores and smooth surface finishes are ideal for intricate laser cutting and engraving projects.

- Avoid plywood with excessive voids, knots, or surface imperfections, as they can lead to inconsistent cutting results and reduced overall quality.

- Opt for plywood with formaldehyde-free or low-emission adhesives to minimize the release of harmful fumes and residues during laser cutting.

- Experiment with different plywood thicknesses to find the optimal balance between cutting speed and edge quality for your specific laser cutting requirements.

But of course, creating a stunning wood laser engraved masterpiece doesn't just depend on the wood material itself but also the laser cutting machine. Here at Monport, we provide you the premium-quality laser cutting machines with an affordable. Check our 60W Co2 laser cutter for example.

Monport 60W CO2 Laser Engraver & Cutter (28" x 20") with Autofocus

Monport 60W CO2 Laser Engraver & Cutter (28" x 20") with Autofocus

Fireproof Viewing Window:

- Crafted from a specialized blend of fire-resistant polyester encased within sturdy iron frames.

- Boasts an impressive set of safety features.

- Melting point ranges from 432° to 488°; ignition temperature surpasses 1000°.

- Acts as a formidable barrier against intense laser heat, significantly minimizing fire hazards.

Enclosed Aeronautical Aluminum Rail:

- Engineered with precision, fortified with X and Y stepper motors.

- Ensures seamless power transmission and meticulous accuracy.

- Crafted from aeronautical-grade aluminum.

- Safeguards against smoke and debris accumulation.

- Extends the longevity of rail units for optimal performance.

Free Laser Protective Glasses:

- Certified to shield against radiation damage from class 4 lasers.

- Safeguards against direct, indirect, or reflected laser light.

- Offers an additional layer of protection for operators in laser-intensive environments.

Ruida Digital Controller:

- Seamlessly adaptable to various software platforms.

- Empowers users with unparalleled control over laser operations.

- User-friendly interface and digital display facilitate effortless operation and customization.

High Speed and Resolution:

- Boasts engraving speeds of up to 800 mm/s and cutting speeds of 400 mm/s.

- Achieves a remarkable resolution of up to 4500 dpi.

- Three LED light strips provide optimal illumination.

- 2.0" focal distance enables high-resolution etching of intricate designs.

Autofocus:

- Simplifies workflow with an innovative autofocus feature.

- Enables automatic correction at the touch of a button.

- Eliminates the need for manual adjustments, enhancing efficiency.

Built-in Air Assist:

- Enhances precision by guiding pressurized air to displace debris, heat, and gases.

- Ensures pristine results and prolongs equipment lifespan.

- Suitable for demanding environments.

3-Way PC Connection:

- Equipped with two USB ports for flash drive connectivity and USB-to-USB PC connection.

- Ethernet port for expanded compatibility.

- Caters to diverse connectivity needs, ensuring seamless integration.

Red Dot Guidance:

- Highlights laser head position, delineates the working path, and frames project sizes with accuracy.

- Enhances workflow efficiency and ensures pinpoint accuracy.

Automatic Safety Sensor:

- Halts machine operation in emergencies, even with the viewing window cover on.

- Resumes operation seamlessly with the press of the "Enter" button.

- Ensures uninterrupted workflow and operator peace of mind.

FAQs

-

What materials can Monport laser machines handle?

Monport lasers work on wood, acrylic, metal, leather, glass, and more—ideal for versatile engraving and cutting. -

What are the benefits of Monport CO₂ laser engravers?

They offer high precision, large work areas, and powerful cutting ability, perfect for creators and small businesses. -

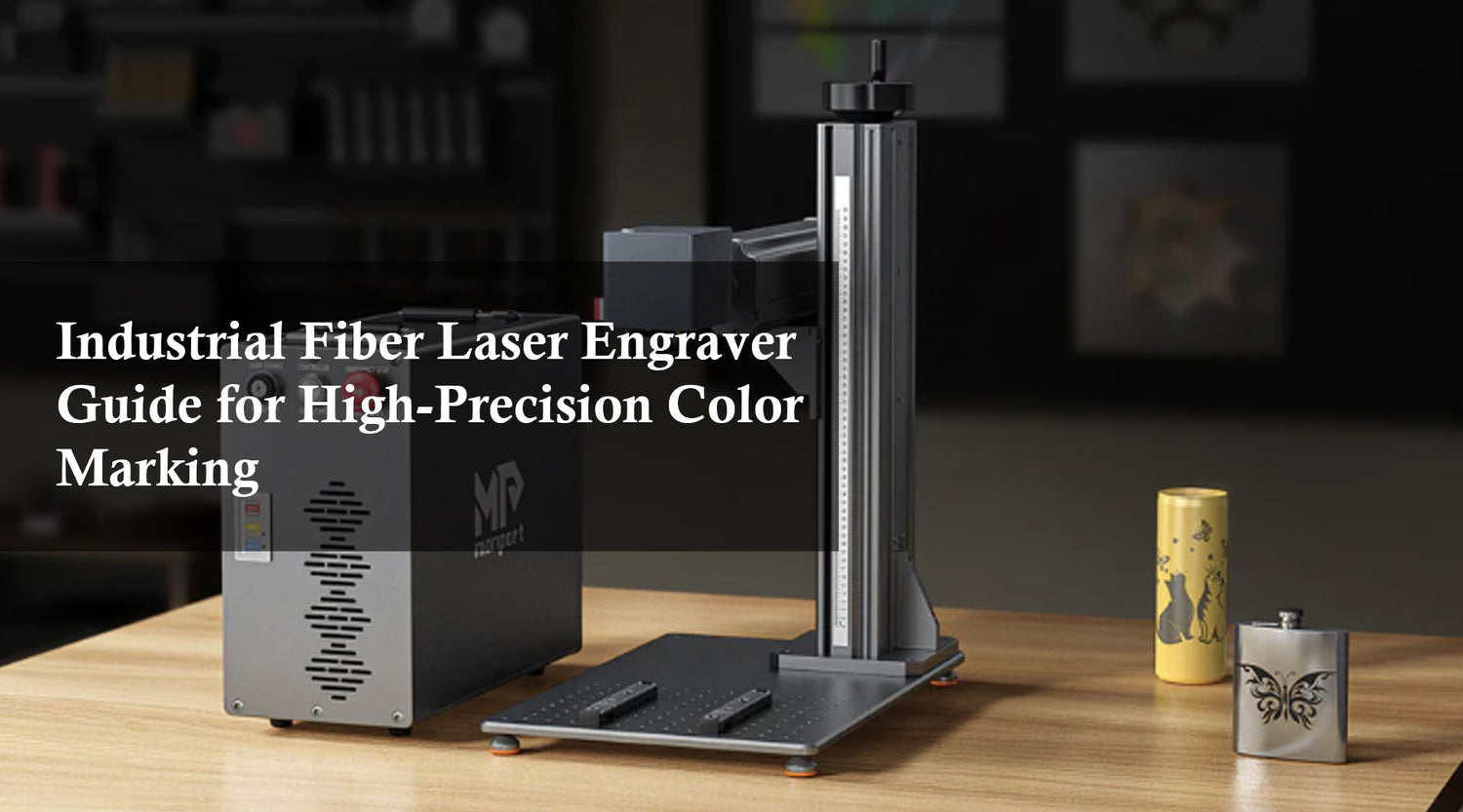

Why choose a Monport fiber laser?

Monport fiber lasers are built for speed and accuracy, making them excellent for metal engraving and industrial use. -

Are Monport machines beginner-friendly?

Yes, many models come pre-assembled or semi-assembled, with intuitive controls and tutorials for easy setup. -

What makes Monport stand out from competitors?

Monport offers affordable pricing, solid build quality, and great software compatibility—ideal for hobbyists and pros alike.

Conclusion

Picking the perfect plywood for laser cutting is a crucial step in achieving optimal results and maximizing the potential of your laser cutting projects. By considering factors such as plywood grade, core material, adhesive type, surface finish, and thickness, you can ensure clean cuts, precise engraving, and consistent quality in your laser-cut plywood creations. So, armed with this knowledge, venture forth and unleash your creativity with confidence in selecting the perfect plywood for your laser cutting endeavors. Visit us now!

Unlock Big Savings at Monport Laser! Use code BESTMP10 at checkout for an exclusive discount – Click here to shop now!